DTF Printer Maintenance Guide for Buyers

Maximize Your DTF Printer’s Lifespan & Performance

Direct-to-Film (DTF) printing is an excellent solution for custom garment and merchandise printing, but like any high-tech equipment, it requires regular maintenance to keep it running smoothly. This guide will walk you through key maintenance tips and considerations for getting the most out of your DTF printer.

Key Considerations Before Purchasing a DTF Printer

-

Daily Use is Crucial

- DTF printers require frequent use to keep the printheads and ink systems functioning properly. If you’re not planning to print every day or frequently, DTF may not be the best fit for you.

- Tip: If you don’t print daily, it might be more practical to outsource your DTF printing to a professional service instead. This can save you from having to invest in regular maintenance and risk damage due to extended idle times.

-

Space & Setup

- Ensure that you have a dedicated space for your DTF printer with a stable, clean environment. Humidity and temperature fluctuations can affect print quality and machine performance.

Daily Maintenance (Before and After Each Print Job)

-

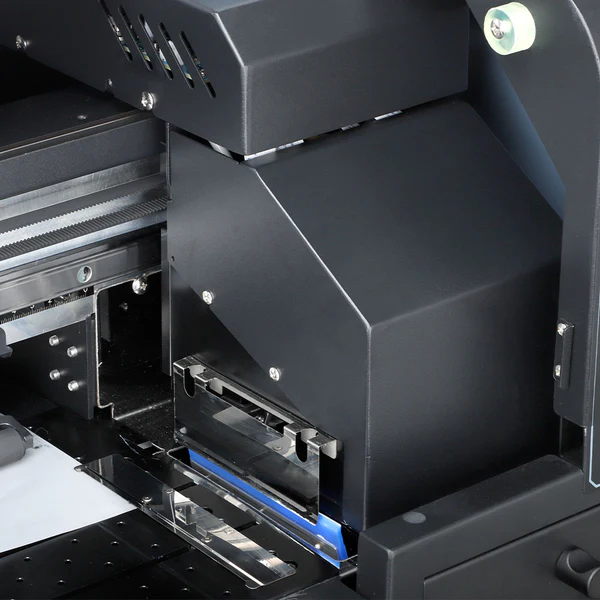

Clean Printheads

- Clean the printheads at the start and end of each printing session to prevent clogging. Use a soft lint-free cloth and isopropyl alcohol to gently wipe the heads.

- Tip: Run a cleaning cycle through your printer if you notice a drop in print quality (banding, missing colors, etc.).

-

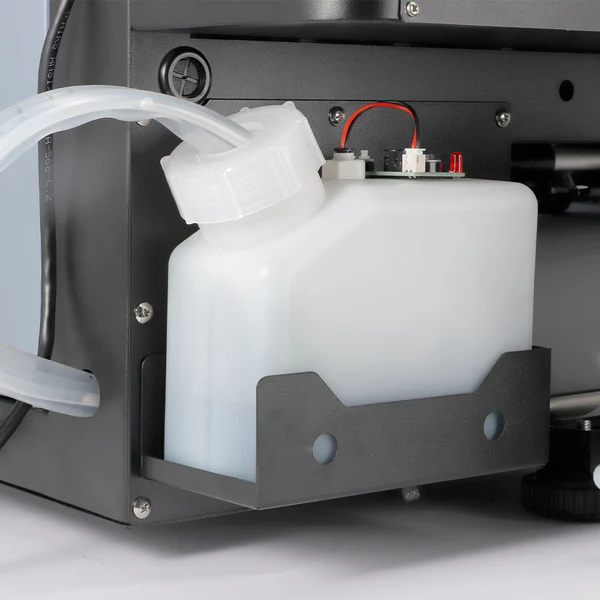

Check Ink Levels

- Always monitor ink levels. Low ink can cause poor print quality and damage the printhead. Make sure to have backup ink on hand.

- Tip: Use high-quality inks that are compatible with your printer to avoid clogging and ensure vibrant prints.

-

Monitor the Printer Bed

- Ensure the printer bed is clean and free of any debris or excess ink that could interfere with the print process. Use a lint roller or soft brush to gently clean the surface.

-

Adjust the Print Settings

- Verify the print settings (speed, temperature, and pressure) before starting each job to ensure optimal results.

- Tip: Run a test print regularly to check for any discrepancies in colors or resolution.

Weekly Maintenance

-

Deep Clean the Printhead

- Perform a deep clean once a week to maintain the best quality and prevent any ink build-up that could lead to printhead damage. Use a cleaning solution specifically designed for DTF printers.

-

Check Ink Flow & Hose Connections

- Inspect all ink hoses and connections for any signs of wear or leaks. Ensure there are no blockages or air pockets in the system.

-

Update Software & Firmware

- Make sure your printer’s software and firmware are up to date. This can help with efficiency, new features, and resolving any bugs or issues.

-

Check for Calibration Issues

- Check the printer for calibration issues and realign the printhead if necessary. This ensures accurate color printing and prevents misalignment.

Monthly Maintenance

-

Perform a Full Printer Cleaning

- At least once a month, perform a comprehensive cleaning of the printer, including the printhead, rollers, and internal components.

- Tip: Follow the manufacturer’s recommended procedure to prevent voiding the warranty or causing any unnecessary damage.

-

Replace Consumables

- Check the condition of consumables like transfer film, ink cartridges, and printhead caps. Replace them as needed to ensure optimal performance.

-

Inspect the Printer’s Electrical Components

- Inspect the power cables, connectors, and other electrical components to ensure everything is in working order.

Troubleshooting Common Issues

-

Clogged Printheads

- Symptoms: Lines or missing colors in prints.

- Solution: Perform a cleaning cycle or manually clean the printhead with alcohol and a lint-free cloth. If the issue persists, contact technical support.

-

Ink Smudging or Transfer Issues

- Symptoms: Ink smudging during transfer or poor adhesion to the fabric.

- Solution: Check the curing temperature and time. Make sure your transfer films are compatible and in good condition. You may need to adjust the heat press settings.

-

Poor Print Quality

- Symptoms: Faded or inconsistent prints.

- Solution: Check ink levels, clean the printhead, and ensure proper calibration. Run test prints regularly to check for consistency.

When to Outsource DTF Printing

While DTF printing offers amazing results, it requires regular maintenance and daily use to keep it in good working condition. If you don’t plan to print daily or lack the resources for consistent upkeep, it may be better for you to outsource your DTF printing. This can help avoid potential problems with your machine and ensure that your prints remain high quality without the added effort of maintenance.

Conclusion

Maintaining your DTF printer is essential to achieving high-quality prints and prolonging the lifespan of the equipment. If you’re committed to regular use and upkeep, a DTF printer is an excellent investment. However, if you’re not planning to print every day, consider outsourcing your DTF printing to professionals for a hassle-free experience.

Ready to Purchase a DTF Printer or Need Help?

Reach out to us for expert advice, support, and a wide range of top-quality DTF printers that suit your business needs!