i3200-A1 DTF Printer 60cm Dual Head

R 208,000.00

- USD: 13,054.42$

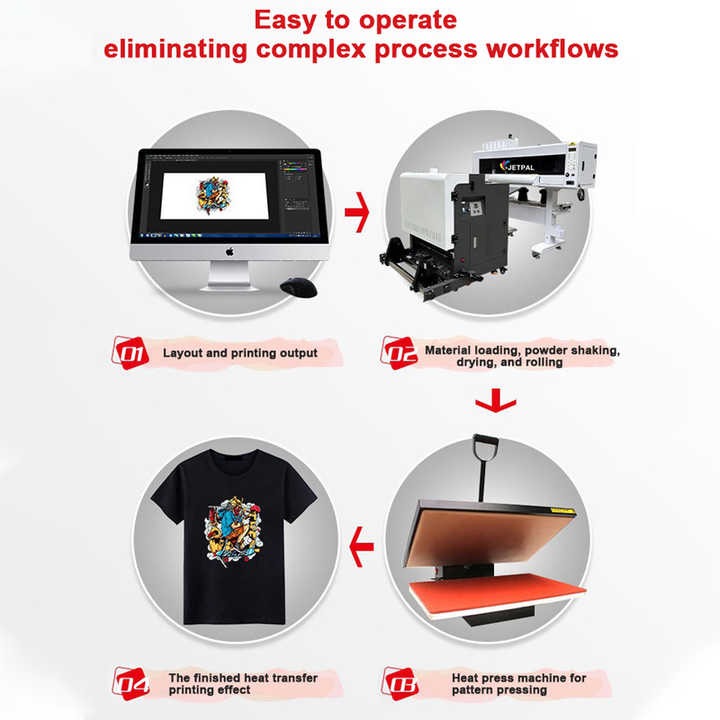

Built for high-demand environments, the JetPal 60cm DTF printer delivers reliable, industrial-grade performance for serious apparel businesses. Whether you’re upgrading or launching your brand, this machine is your gateway to producing vibrant, full-color prints on any fabric, at impressive speeds.

🔹 JetPal 60cm Dual i3200-A1 DTF Printer

- Availability: In Stock – Ready for Immediate Delivery

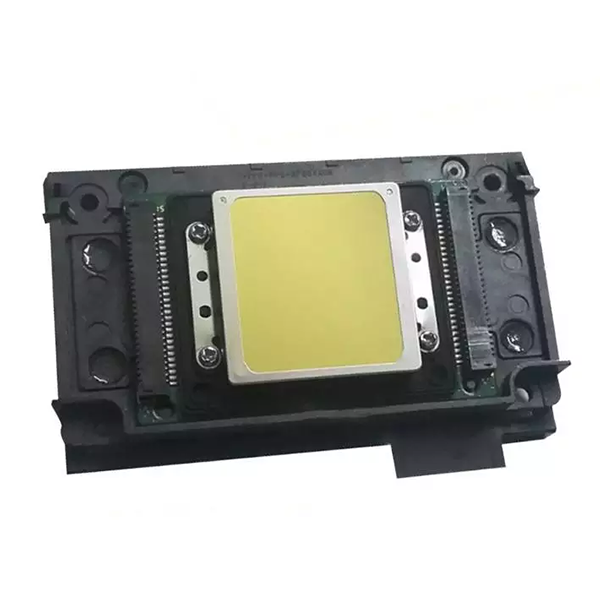

- Printhead Options: Epson XP600 or Industrial i3200

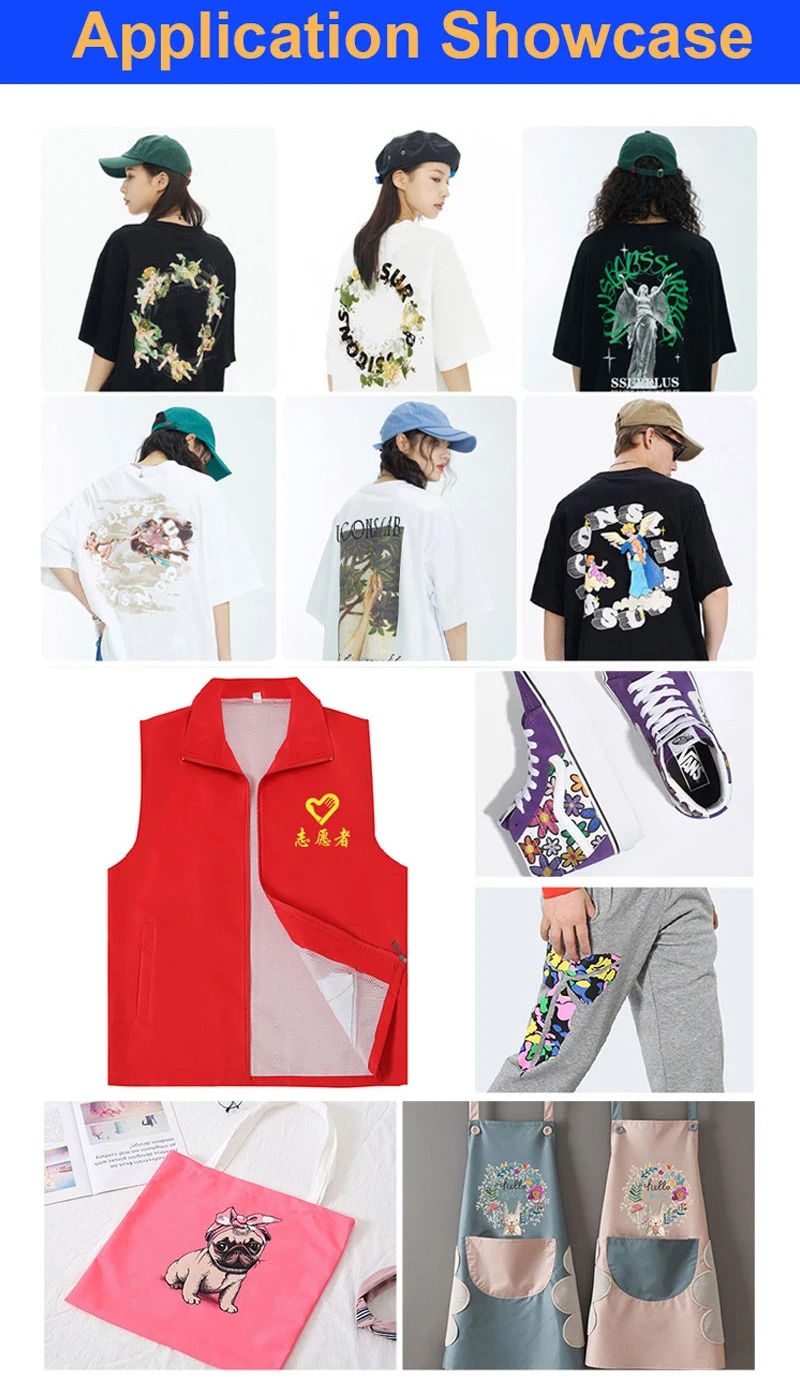

- Ideal For: T-Shirts, Cotton & Polyester Fabrics, Hoodies, and More

Description

JetPal 60cm DTF Printer – High-Speed, Professional Results

Built for high-demand environments, the JetPal 60cm DTF printer delivers reliable, industrial-grade performance for serious apparel businesses. Whether you’re upgrading or launching your brand, this machine is your gateway to producing vibrant, full-color prints on any fabric, at impressive speeds.

🔹 JetPal 60cm Dual i3200-A1 DTF Printer

- Availability: In Stock – Ready for Immediate Delivery

- Printhead Options: Epson XP600 or Industrial i3200

- Ideal For: T-Shirts, Cotton & Polyester Fabrics, Hoodies, and More

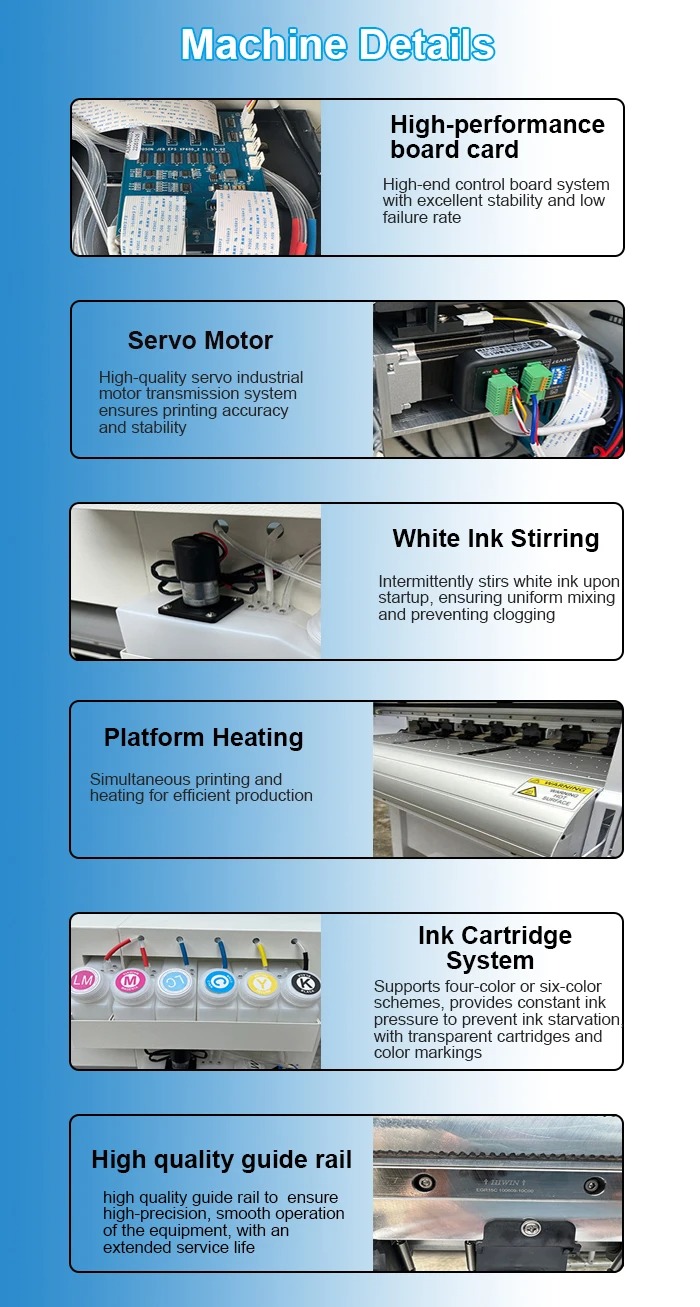

🛠 Technical Specifications

| Feature | Details |

|---|---|

| Model | JP-DTF602 |

| Max Print Width | ≤650mm (60cm film compatible) |

| Printheads | Dual XP600 or Dual i3200 |

| Print Resolutions | Up to 3200 DPI |

| Print Speed | XP600: 6pass 5m²/h, 8pass 3m²/h i3200: 6pass 7m²/h, 8pass 5m²/h |

| Ink | DTF Pigment Ink – CMYK+White |

| Media | PET Heat Transfer Film |

| Nozzle Cleaning | Automatic |

| Rewind Function | Sensor-driven Auto Winding |

| Software | Maintop / Photoprint RIP |

| Connection Interface | USB 3.0 / Gigabit Ethernet |

| Operating System | Windows 7 / Windows 10 Home |

| Working Environment | 15–30°C, 40–60% Humidity |

| Power Consumption | ~250W ±5% |

🧰 Bundle Includes

- ✔️ RIP Software (Maintop/Photoprint)

- ✔️ Powder Shaker & Dryer (Optional Add-on)

- ✔️ Automatic Cleaning and Suction Platform

- ✔️ Remote Setup Assistance

- ✔️ Nationwide Delivery & After-Sales Support

💡 Why Choose JetPal DTF?

- Industrial-level output with compact footprint

- Supports large-format 60cm PET film

- Compatible with a wide range of fabrics – cotton, polyester, blends

- Smooth gradient prints with sharp detailing and strong color

- Designed for continuous production and commercial scalability

Whether you’re printing for fashion, branding, or custom merch, the JetPal 60cm DTF delivers speed, quality, and value.

💬 Contact us today to schedule a demo or request a full quotation.

📍 Available nationwide – We deliver anywhere in South Africa.

Related products

-

DTF Printer 13″ A3 Dual XP600 & DTF Shaker Bundle

R 222,342.54Add to cart- USD: 13,954.58$

-

Three Bundle A3 DTF Starter – for T-Shirts, Bags, Hats & More

R 147,900.00Add to cart- USD: 9,282.45$

-

A3 LED UV production workhorse offers advanced 3D textured and embossed photorealistic printing

R 287,900.00Add to cart- USD: 18,069.07$

-

PET A3 DTF Film Printer designed for high-quality direct-to-film (DTF) printing

R 235,000.00Add to cart- USD: 14,748.98$

-

DTF A4 + DTF Shaker Oven with Purifier for beginners

R 97,000.00Add to cart- USD: 6,087.88$

-

Yinghe A3 30cm DTF Printer – High-Quality Direct-to-Film Printing

R 115,000.00Add to cart- USD: 7,217.59$

-

Artis 5000U The B2 Small LED UV Production Printer, Print BIG and up to 70cm by 50cm

R 382,400.00Add to cart- USD: 24,000.05$

-

Rolled DTF Film Powder Shaking and Baking Machine 300mm

R 17,658.00Add to cart- USD: 1,108.24$

-

Seismo M24 Powder Shaker 60cm Width

R 142,900.00Add to cart- USD: 8,968.64$

-

A4 DTF Bundle + Heat Press

R 82,094.00Add to cart- USD: 5,152.35$