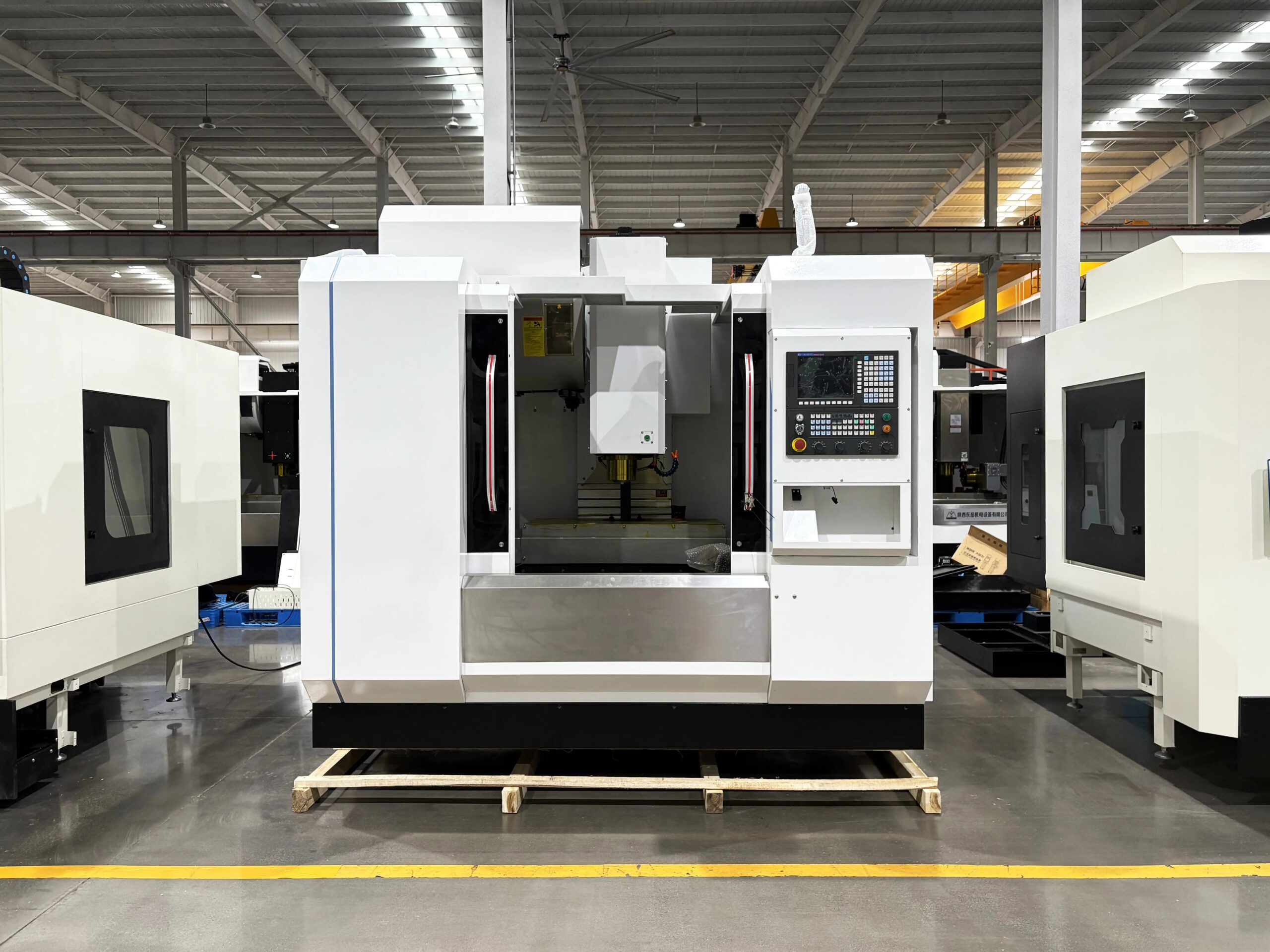

Milling Machine VMC1160 CNC Vertical Machining delivers stable cutting for heavy-duty production.

R 1,300,000.00

- USD: 81,093.39$

VMC1160 CNC Vertical Machining delivers stable cutting for heavy-duty production.

No vibration. Strong rigidity. Consistent accuracy.

Built for factories producing precision metal parts at scale.

This machine handles steel, stainless steel, aluminium, brass plus general machined parts.

Design supports long run jobs with low maintenance demand.

Why buyers choose VMC1160

• Stable structure for heavy cutting

• High positioning accuracy

• Fast tool change for higher output

• Multiple CNC system options

• Strong casting with long service life

Available on backorder

Category: Laser And CNC Machine

Description

PRODUCT SPECIFICATION TABLE

| Product Name | VMC1160 CNC Vertical Machining Center |

|---|---|

| Machine Type | Vertical CNC milling machine |

| Working Table Size | 1200 x 600 mm |

| X Axis Travel | 1100 mm |

| Y Axis Travel | 600 mm |

| Z Axis Travel | 600 mm |

| Max Table Load | 800 kg |

| Spindle Taper | BT40 or BT50 |

| Spindle Speed | 8000 rpm (Optional 10000 or 12000 rpm) |

| Main Motor Power | 11 kW or 15 kW |

| Positioning Accuracy | ±0.0075 mm |

| Repeat Positioning Accuracy | ±0.005 mm |

| Rapid Traverse Speed | 36 m per minute on X, Y, Z |

| Cutting Feed Speed | 1 to 10000 mm per minute |

| Tool Magazine | 24 arm type |

| Tool Change Time | 2 seconds |

| Max Tool Weight | 8 kg |

| Machine Weight | 6500 kg |

| Overall Dimensions | 3400 x 2480 x 2960 mm |

| Voltage | 220V or 380V |

| CNC Control Options | Fanuc, Mitsubishi, Siemens, Syntec, GSK |

CORE COMPONENTS

Machine casting uses HT300 high strength grey iron.

Double aging treatment improves rigidity and lifespan.

Spindle uses Taiwan high precision unit.

Smooth rotation with strong surface finish.

Linear guide rails from HIWIN or PMI.

Low noise. High accuracy. Long service life.

Ball screw system uses C3 grade with double pre-tightening.

Accuracy stays consistent during long operation.

Electrical system uses Schneider components.

Safe layout with quick plug design.

Lubrication uses automatic centralized system.

Timed and controlled oil delivery.

Pneumatic system uses AirTAC components.

OPTIONAL CONFIGURATION

Fourth axis rotary table supports full 360 degree indexing.

Fifth axis option supports complex multi-angle machining.

Chain type chip conveyor improves chip removal efficiency.

Inspection uses Renishaw laser interferometer and ball bar system.

Track straightness and spindle accuracy tested before delivery.

WARRANTY AND SUPPORT

One year warranty included.

Machine test report provided.

Outgoing inspection video provided.

Factory inspection supported.

Related products

-

1325 CNC Router Starter (Vacuum bed)

R 238,250.00Add to cart- USD: 14,861.92$

-

1325 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining

R 564,250.00Add to cart- USD: 35,197.65$

-

1300x900mm Cabinet Laser Cutting & Engraving Machine 100W CO2 Laser

R 123,000.00Add to cart- USD: 7,672.68$

-

50W CNC Laser Engraver DIY Logo Mark Printer Cutter Laser Photo Engraving Machine

R 33,000.00Add to cart- USD: 2,058.52$

-

Ceramic Colour Fiber Laser Marking Paper, 24×36cm – 20 Sheets Per Bag

R 1,800.00Add to cart- USD: 112.28$

-

Laser Cutter & Engraver 300 x 400mm with 40W laser power

R 60,244.00Add to cart- USD: 3,757.99$

-

1325 CNC Router Starter

R 205,250.00Add to cart- USD: 12,803.40$

-

Laser Cutter & Engraver 80W for small to large businesses powerful laser machine 600 x 400mm

R 79,362.00Add to cart- USD: 4,950.56$

-

30W Optical-Fiber Laser Marking Machine (220×220mm Lens)

R 72,580.00Add to cart- USD: 4,527.51$

-

Label Mark 20W Optical-Fibre Laser Marking Machine

R 62,890.00Add to cart- USD: 3,923.05$