Description

Procolored F13 Pro Panda DTF Printer 13″ A3 Dual XP600 & DTF Shaker Bundle

High-Performance Direct-to-Film Printing Solution for Small Businesses

Transform your small business with the Procolored F13 Pro Panda DTF Printer 13″ A3 Dual XP600 & DTF Shaker Bundle. Designed for t-shirt customization and other garment printing needs, this advanced Direct-to-Film (DTF) printer delivers industrial-grade quality, exceptional speed, and unmatched reliability. Whether you’re a beginner or an established small business owner, the F13 Pro Panda offers the perfect balance of performance and ease of use.

Why Choose the Procolored F13 Pro Panda DTF Printer?

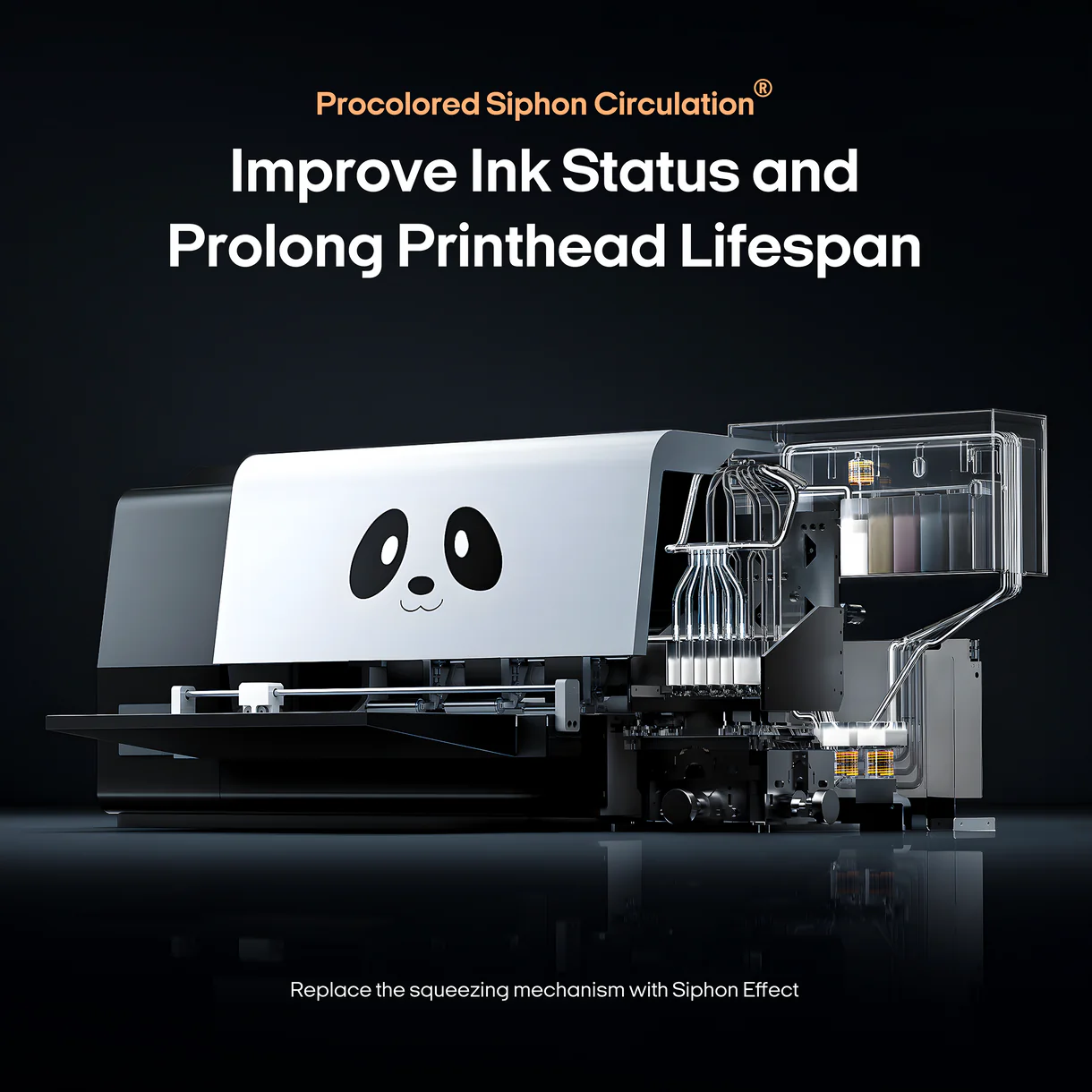

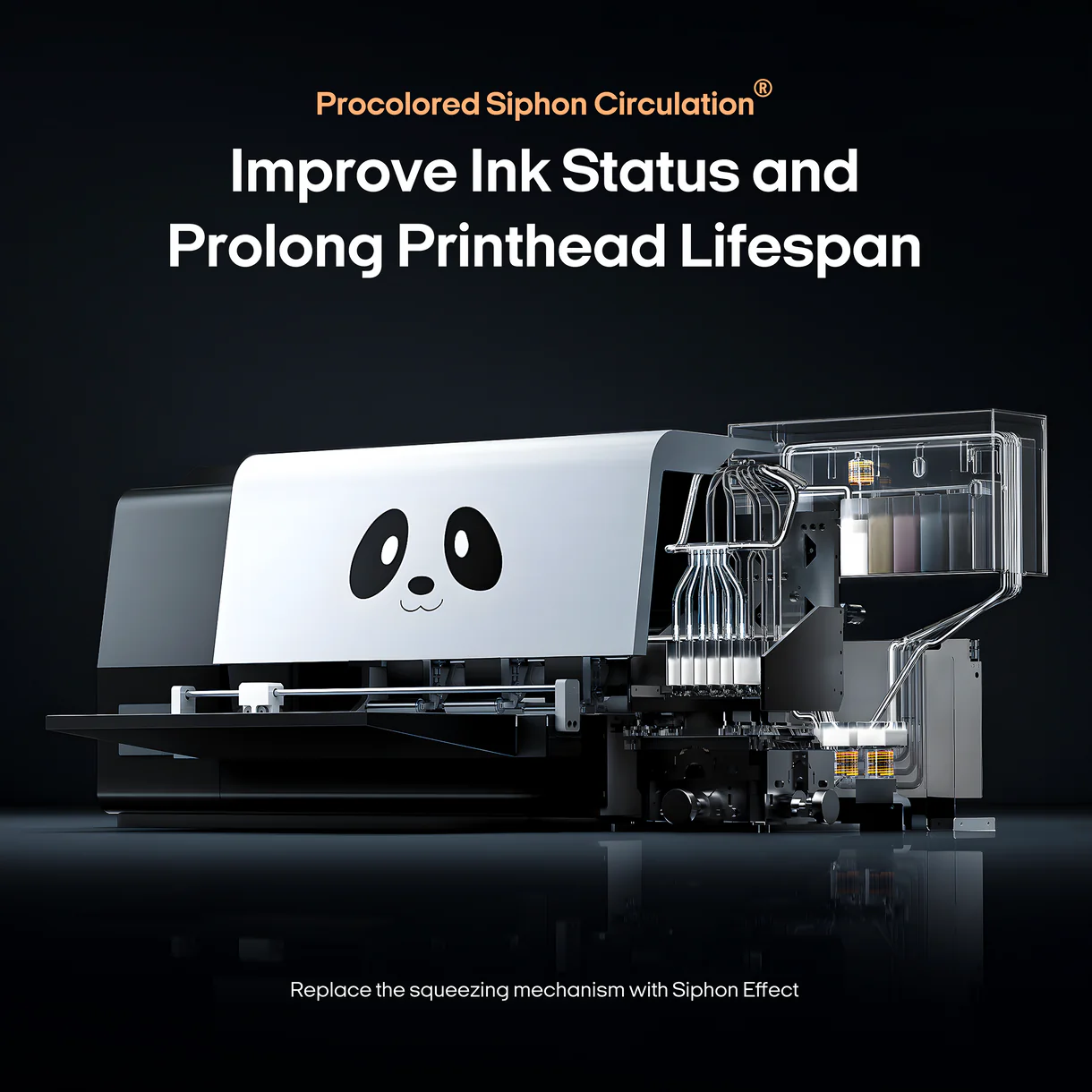

- Advanced Procolored Siphon Circulation® Technology:

- 50% Less Clogging: Minimizes printhead clogs, ensuring smooth and continuous printing.

- 50% Less Maintenance: Reduces upkeep requirements, allowing you to focus more on your business.

- More Time for Success: Enhanced efficiency boosts productivity and output quality.

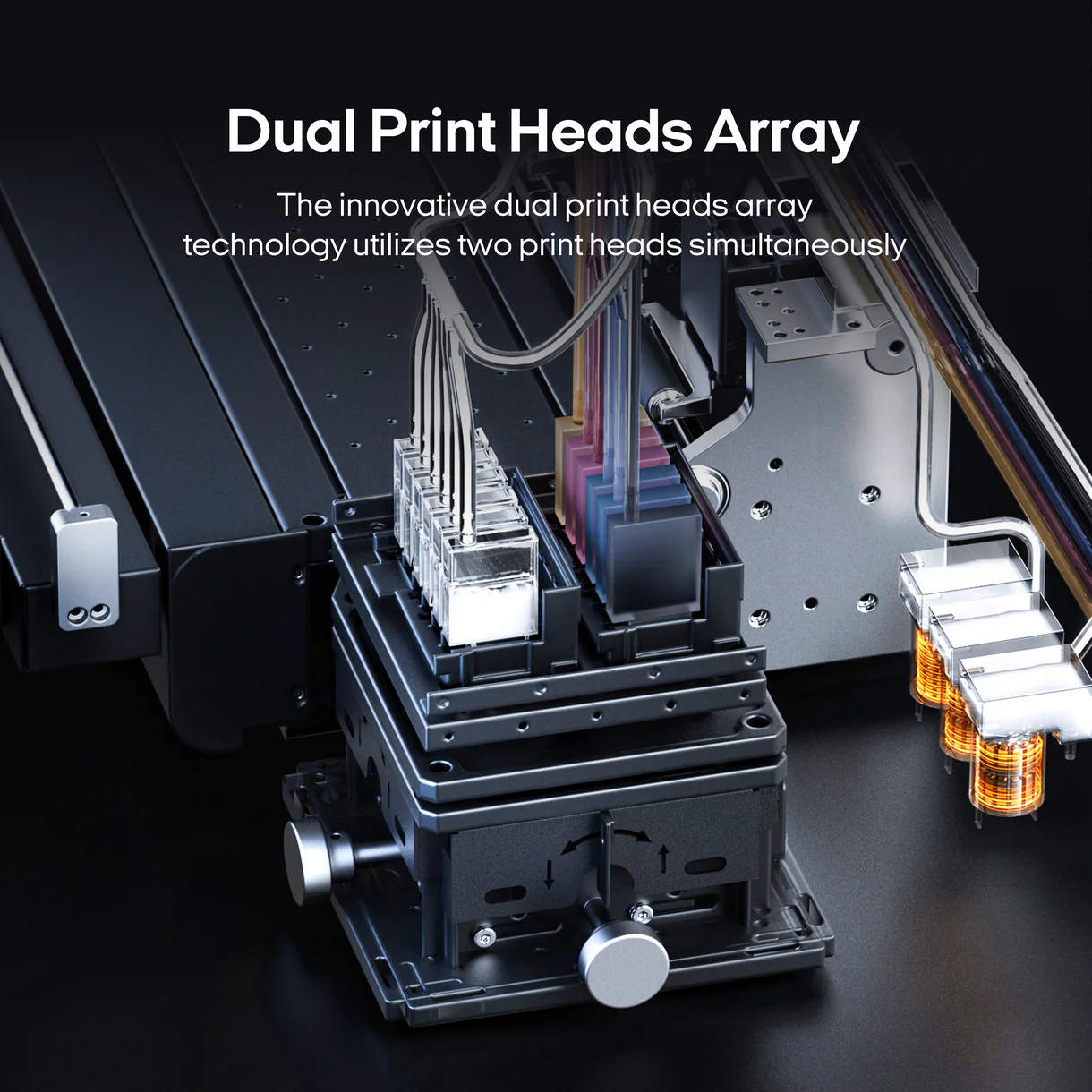

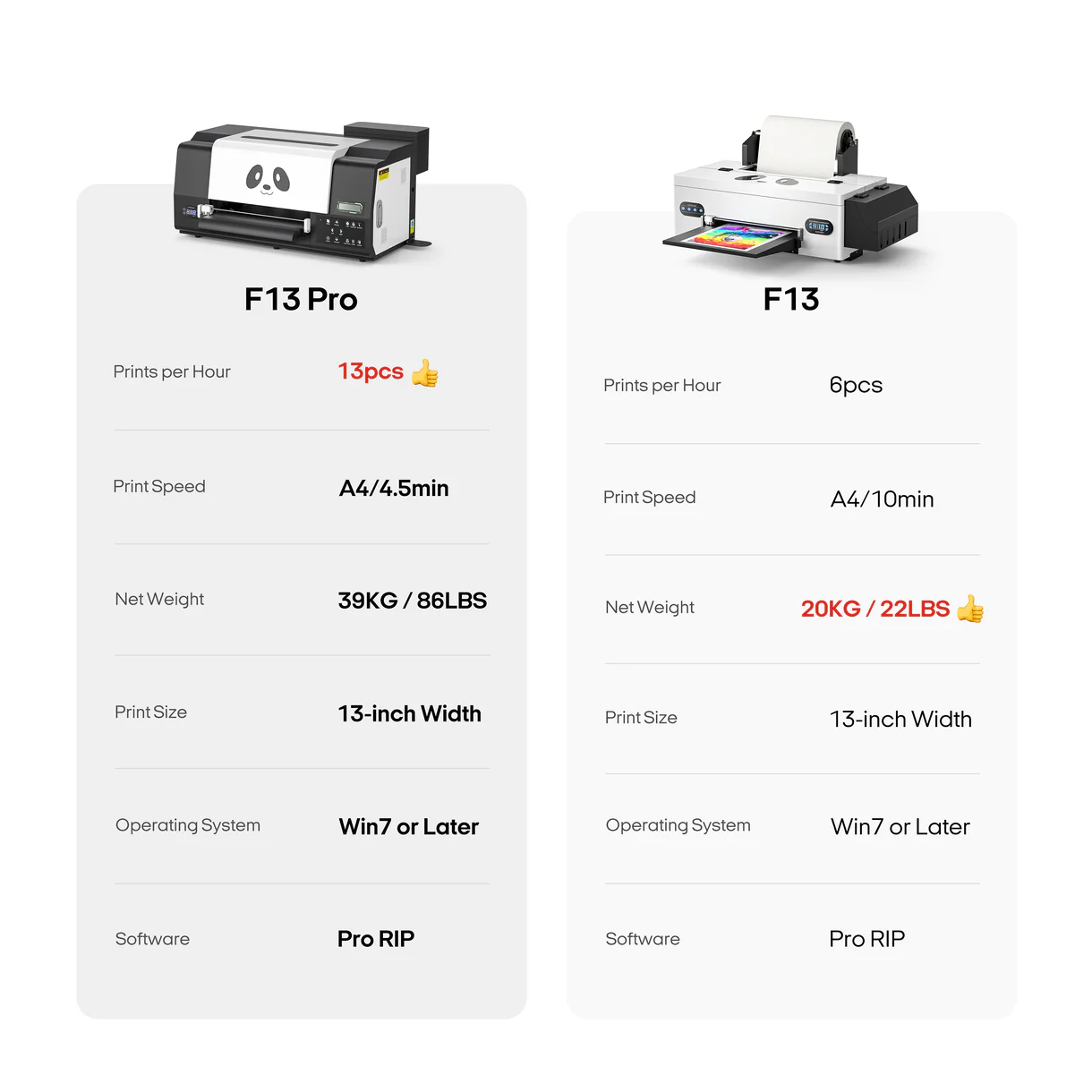

- Dual Print Heads for Enhanced Performance:

- Higher Printing Efficiency: Dual XP600 print heads work simultaneously, doubling your printing speed.

- Industrial-Grade Quality: Produces high-resolution, vibrant, and durable prints with minimized color distortion.

- User-Friendly Design:

- No Pretreatment Required: Simplifies the printing process, making it accessible for users with no prior experience.

- Easy Operation: Streamlined steps and intuitive controls ensure a hassle-free printing experience.

- Procolored Siphon Circulation® Gen-2:

- Enhanced Ink Circulation: No mechanical squeezing, reducing the risk of ink supply breakdown.

- Extended System Lifespan: Achieves up to 50,000 continuous and stable prints on a whole film roll.

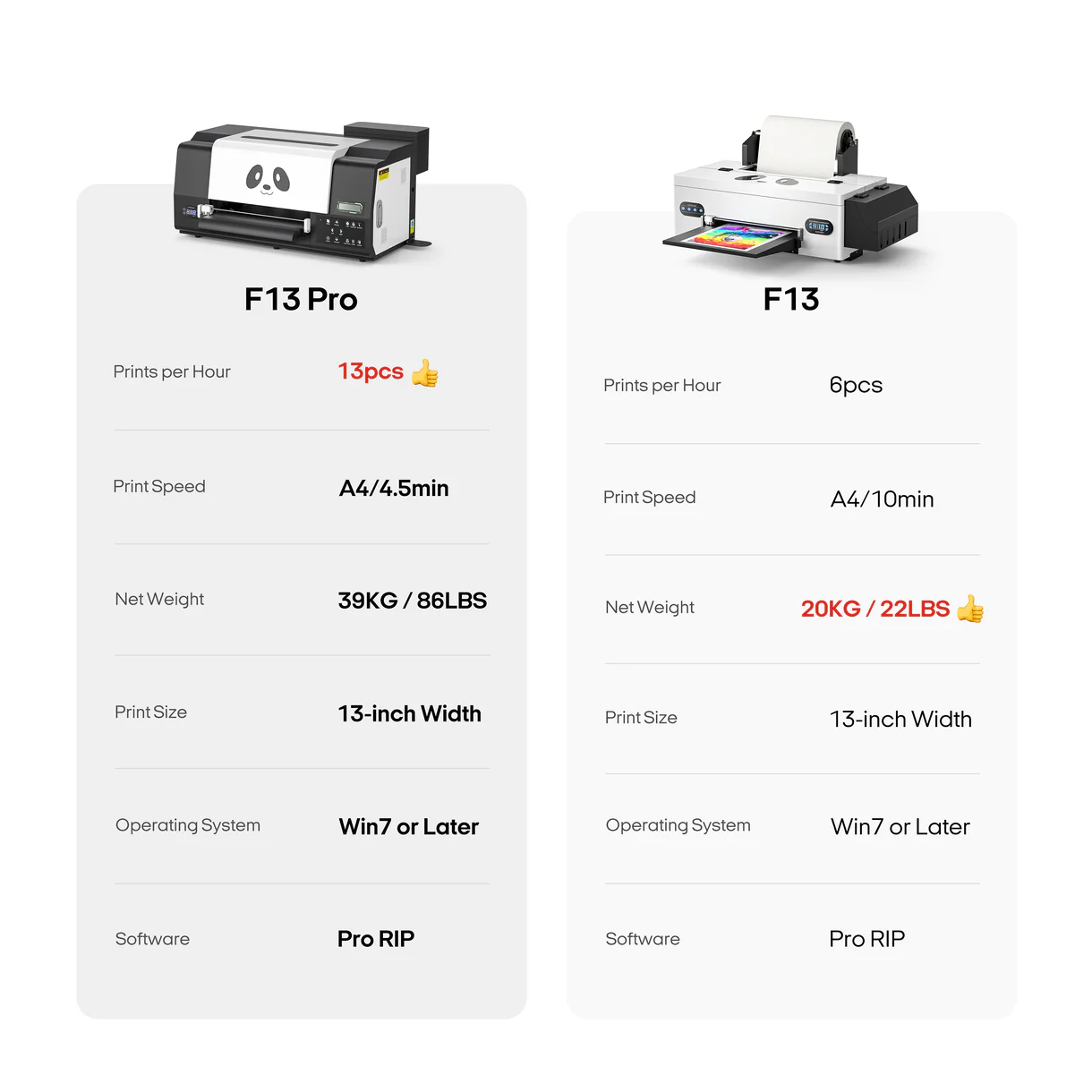

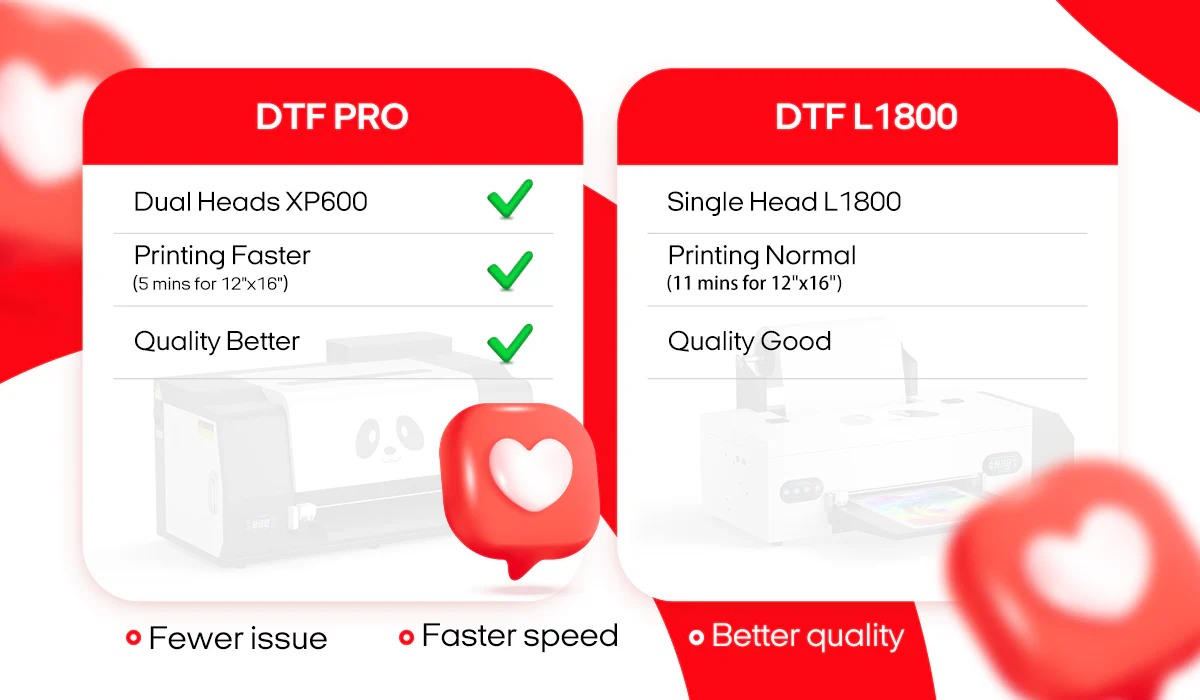

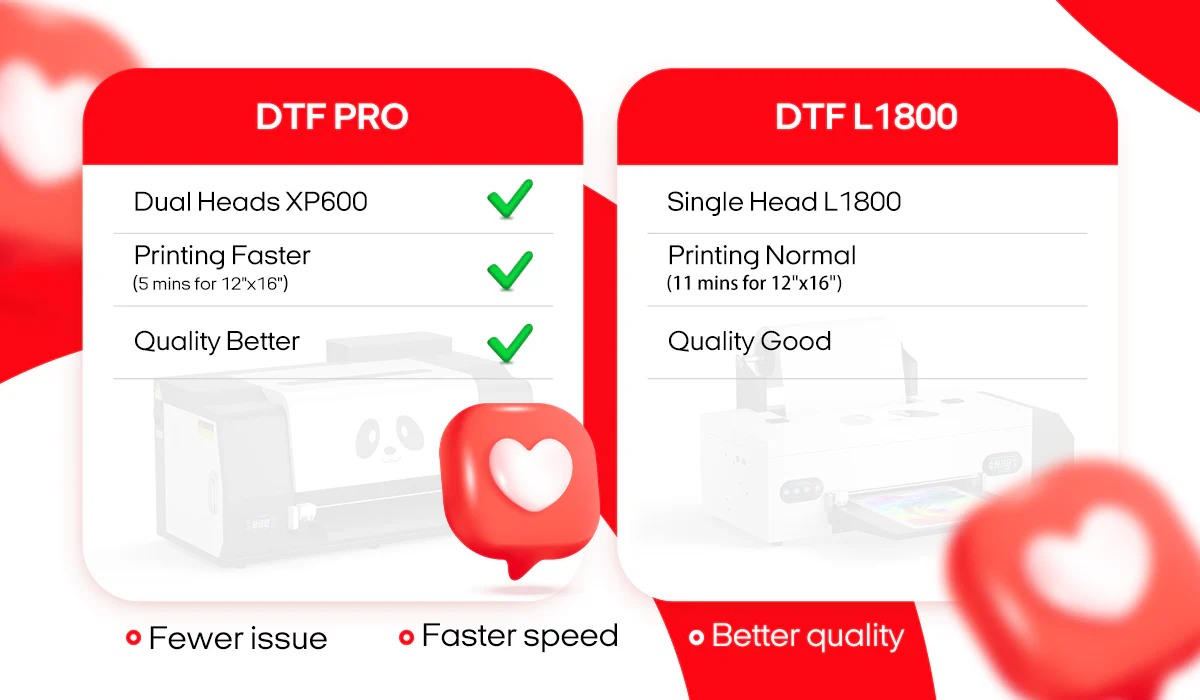

- Significant Advantages Over DTF L1800:

- Enhanced Reliability and Performance: Reduces machine failure and ensures consistent high-quality prints.

- Faster Printing Experience: Dual print heads significantly cut down waiting times, boosting overall productivity.

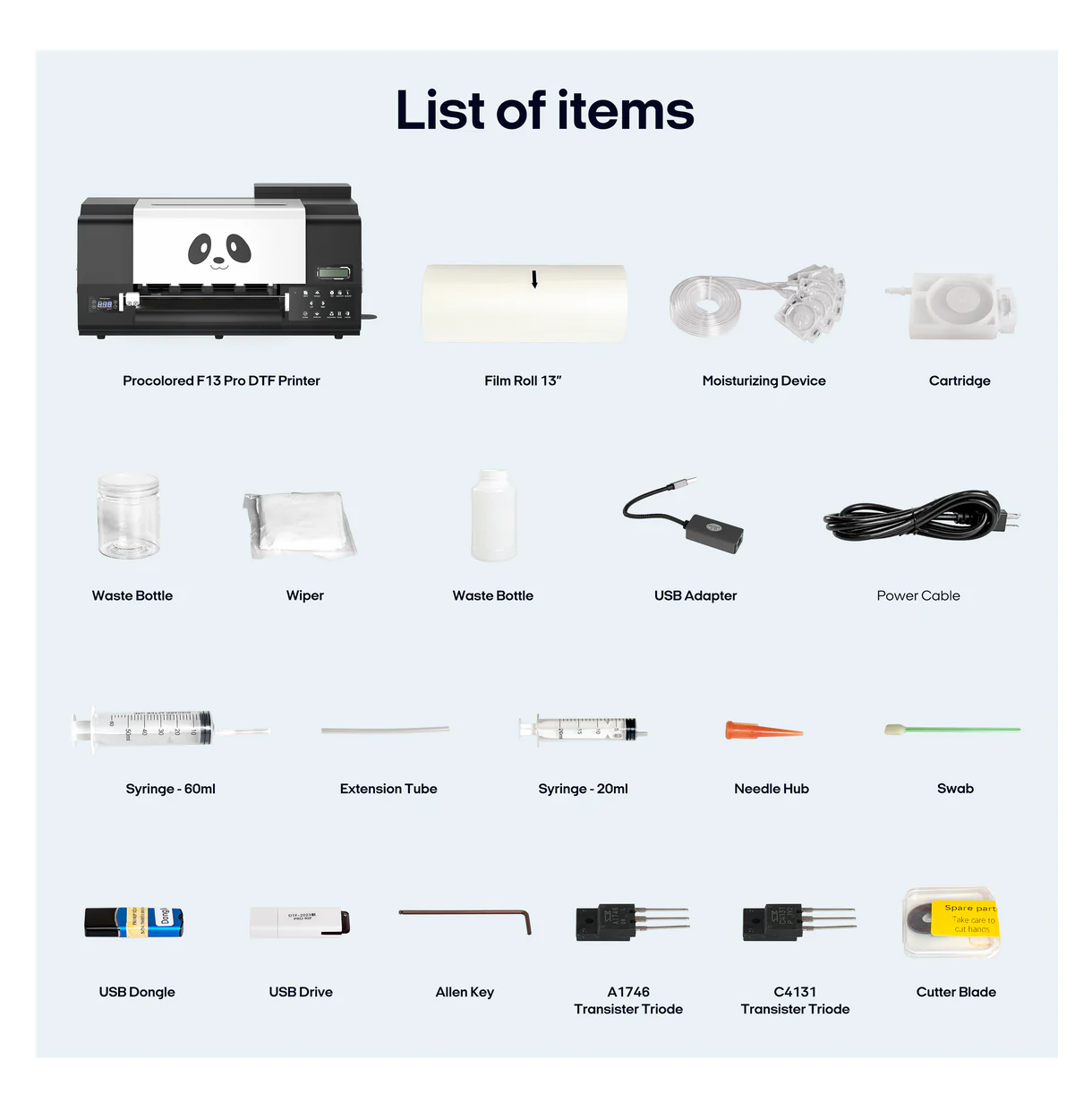

What’s Included in the Bundle?

- F13 Pro Panda DTF Printer

- Powder Shaking and Drying All-In-One Machine

- Full Set of Initial Inks (CMYKW 5x500ml)

- 1000g Adhesive Powder

- Protective Printhead Moisturizing Device

- PET Roll Film

- Procolored RIP Software (Windows OS only)

- Power Cable/USB to Ethernet Adapter

- Ink Tube, Dust-Free Cloth, and Syringe

Note: Ink and powder are shipped separately and are not included in the printer package.

Overview

The Procolored F13 Pro Panda DTF Printer is a user-friendly, high-efficiency Direct-to-Film (DTF) printer equipped with dual print heads, capable of delivering industrial-grade print quality at remarkable speeds. Ideal for small t-shirt customization businesses, this A3 DTF printer offers flexibility and reliability, allowing you to print on various fabrics without composition restrictions. It effectively addresses the limitations of DTG printing and sublimation printing, making it a superior choice for versatile garment printing needs.

Key Features

- Upgraded Appearance:

- Redesigned Lightweight Structure: Combines aesthetic appeal with robust functionality, enhancing your printing workspace.

- Printhead Auto-Cleaning:

- Automatic Maintenance: Cleans the printhead every 10 hours when the printer is left on, consuming about 1ml of ink per day to maintain optimal performance.

- Dual Print Heads:

- Increased Efficiency: Dual XP600 print heads enhance printing speed and quality, ensuring high-resolution, industrial-grade outputs.

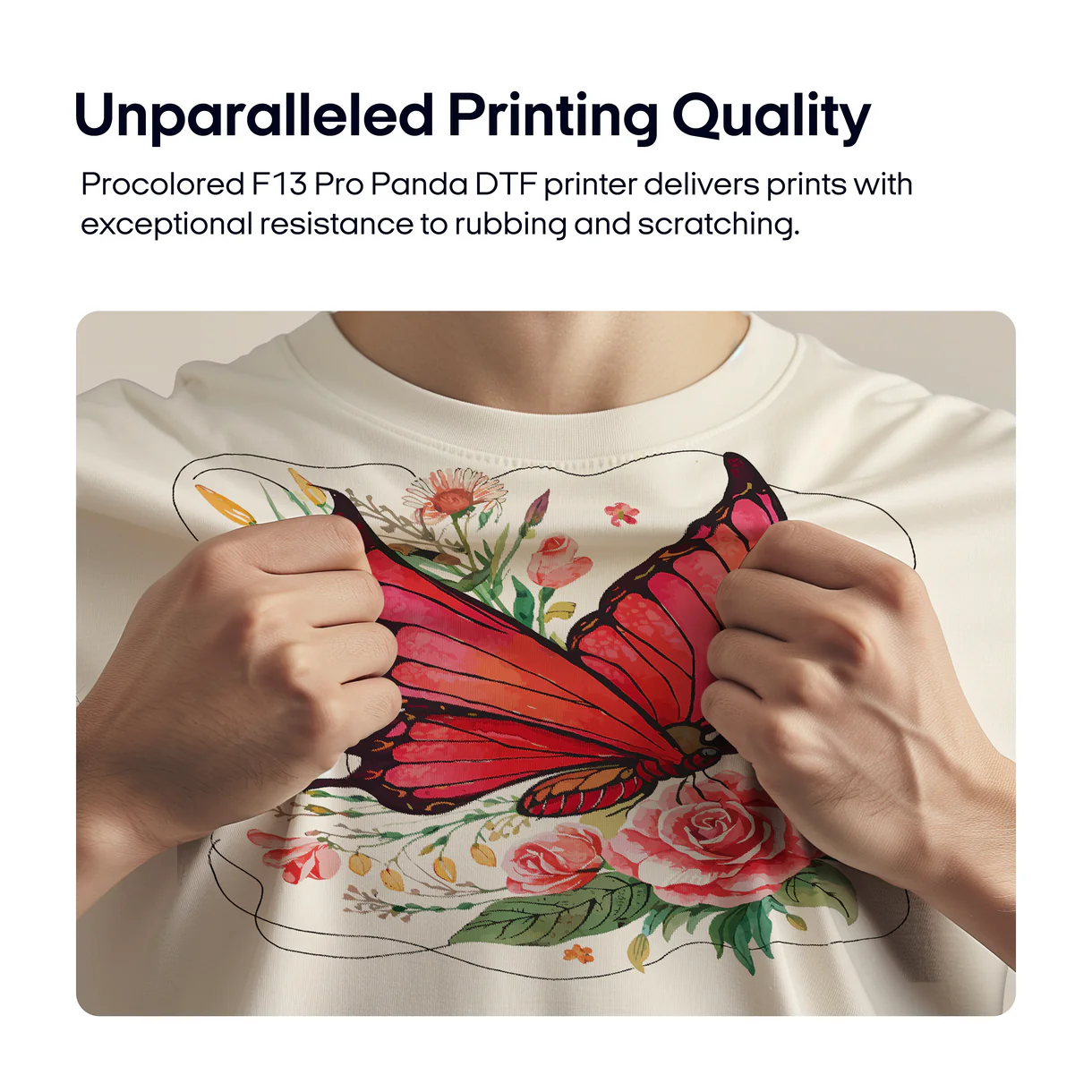

- Extraordinary Printing Quality:

- High-Resolution Patterns: Achieves detailed and vibrant prints with minimized color distortion, perfect for professional branding and customization.

- Procolored Siphon Circulation® Gen-2:

- Reliable Ink Supply: Eliminates mechanical ink pipeline squeezing, reducing maintenance and extending the circulation system’s lifespan.

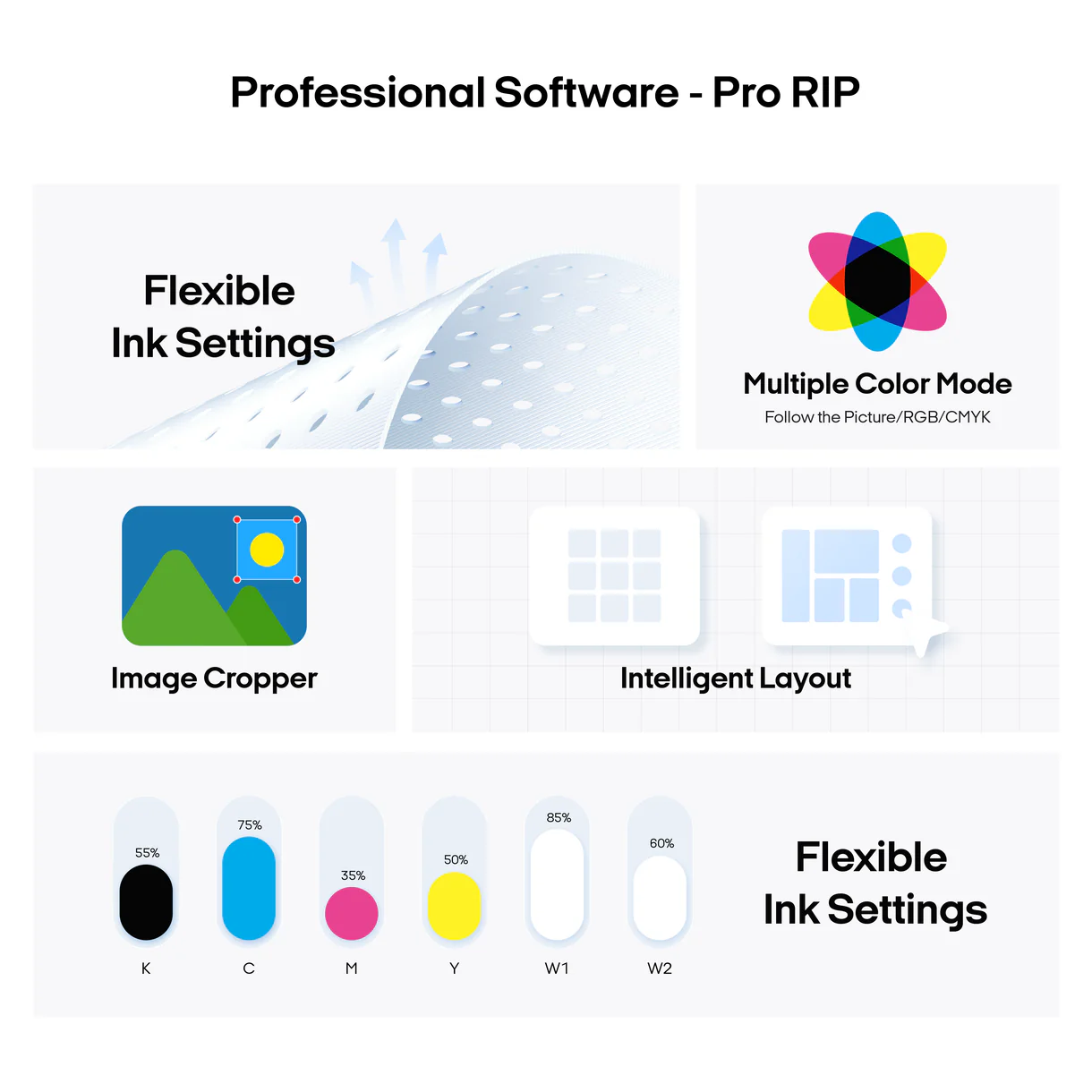

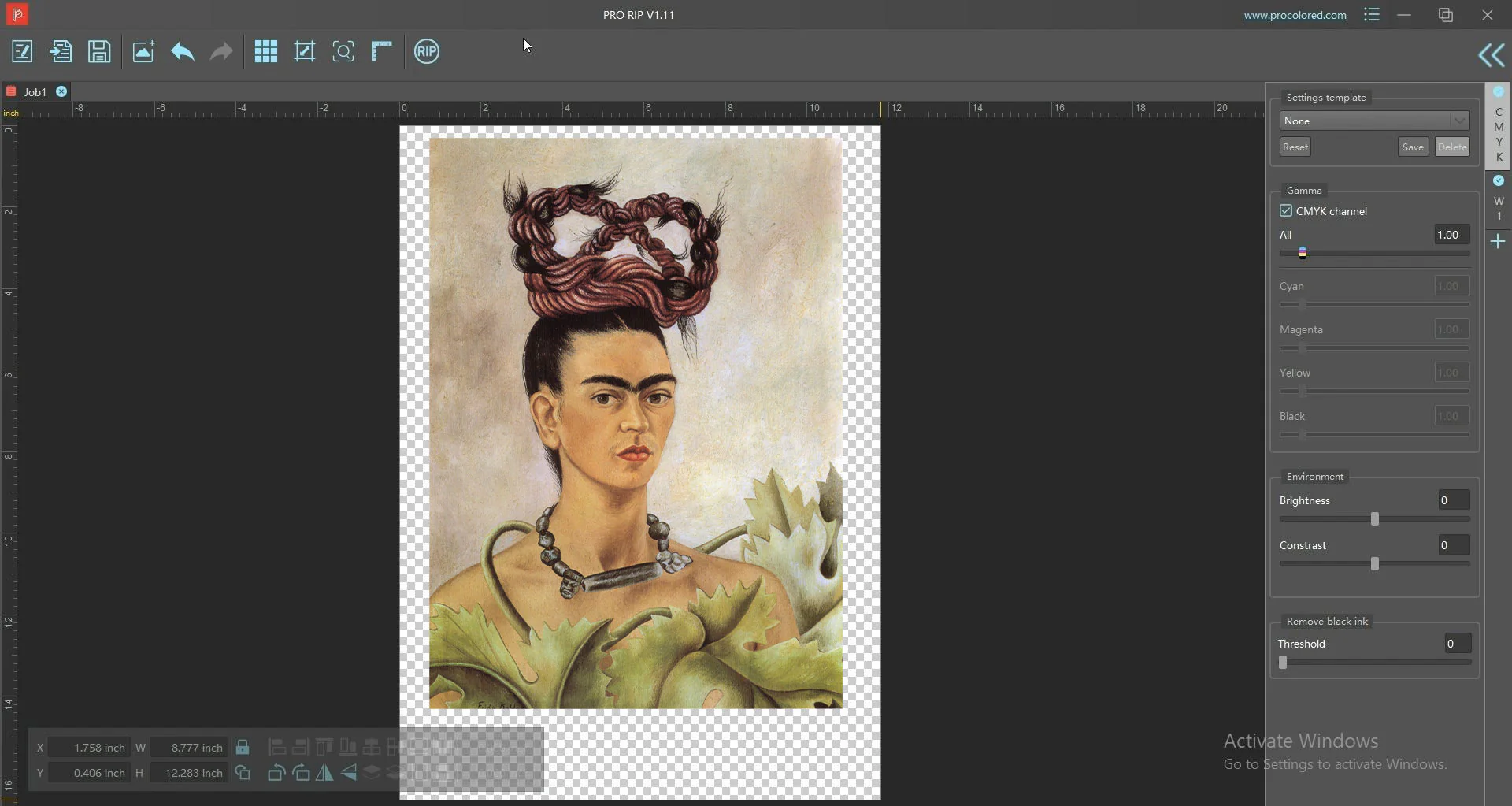

- Professional RIP Software – Procolored RIP:

- Advanced PDF Engine: Features grid algorithms, image splitting, seamless copying, and visual dot rationing.

- High-Speed Processing: Supports standard ICC profiles and personalized workflows for efficient label design and printing.

- Profitable Printing Solutions:

- Multiple Models Available: Choose from three different models to match your business scale and printing needs, ensuring a perfect fit for your operations.

Printing Steps

- Adjust Design: Spend 15-20 seconds fine-tuning your label design.

- Print: Initiate the printing process, which takes approximately 5-8 minutes.

- Spread Powder: Quickly apply adhesive powder in just 5 seconds.

- Oven Dry: Dry the printed labels in the oven for 3 minutes.

- Heat Press: Apply heat press for 20 seconds to transfer the design.

- Peel Off Film: Remove the film effortlessly in 3 seconds, revealing your high-quality label.

Frequently Asked Questions (FAQs)

What is the difference between the DTF L1800 and DTF R1390?

The main difference lies in the motherboard. The DTF R1390 requires manual resetting of the ink volume counter occasionally, whereas the DTF L1800 does not.

How does the DTF L1800 compare to the DTF PRO?

The DTF PRO features two print heads, enabling it to print twice as fast as the DTF L1800, which only has one print head.

Is the RIP software compatible with MacBooks?

No, the Procolored RIP Software is only compatible with Windows OS. Mac users can utilize software like Parallels or Bootcamp to run the RIP software.

Do I need to pay for the RIP software? Can I edit my designs with it?

The Procolored RIP Software is free but requires a software dongle to use. It is designed for image ripping and does not support image editing. Use software like Photoshop or Canva for designing your labels.

What is the after-sales warranty policy and where can I get technical support?

For detailed warranty information, visit our Warranty Policy. For technical support, check our Support and Services.

What is the printing cost for one print?

It costs approximately $1.80 to print a 13″x16″ adult t-shirt.

Can I use multiple payment methods or financing options?

Yes, you can split payments using two cards or opt for Klarna installment plans available on our website. Contact us for more details.

What is the maximum length for roll film printing?

You can print up to 31 inches for a single print job.

How fast can the printer operate?

The F13 Pro Panda can print 4 square feet per hour, making it ideal for medium-scale production.

Is the maintenance process complicated?

No, weekly maintenance only takes a few minutes. For a detailed guide, refer to this maintenance video.

Why Choose Procolored F13 Pro Panda DTF Printer?

The Procolored F13 Pro Panda DTF Printer offers a comprehensive printing solution that combines high-speed performance, exceptional print quality, and user-friendly operation. With advanced features like dual print heads and Procolored Siphon Circulation®, this printer ensures efficient and reliable production, making it the ideal choice for small businesses looking to scale their custom apparel operations.

Pre-order now to take advantage of the Procolored F13 Pro Panda’s outstanding features and competitive pricing, and elevate your printing business to new heights!

Optimize Your Printing with Procolored

Boost your business’s productivity and quality with the Procolored F13 Pro Panda DTF Printer 13″ A3 Dual XP600 & DTF Shaker Bundle. Perfect for t-shirt customization and versatile enough for various garment printing needs, this printer is designed to meet the demands of modern small businesses, providing you with the tools you need to succeed.

Order today and experience the future of DTF printing with Procolored!

SourcePrinting Quality Warranty

At SourcePrinting, we provide a limited product warranty on machine parts for the specified periods, including relevant subsystems. This warranty covers defects due to faulty materials or poor craftsmanship during manufacturing. However, it does not cover normal wear and tear or misuse of the machine or its parts.

Printhead – No Warranty

The printhead is a consumable with a limited lifespan and is highly sensitive to voltage fluctuations. Even with an automatic cleaning system, clogging can occur over time, requiring proper maintenance. Partial clogging is expected during usage, even with regular manual cleaning.

✅ For printers purchased from SourcePrinting: We provide training on printhead care during installation.

❌ For third-party machines: We do not offer installation services for separately purchased printheads.

DTF Printer Maintenance Guide for Buyers

Maximize Your DTF Printer’s Lifespan & Performance

Direct-to-Film (DTF) printing is an excellent solution for custom garment and merchandise printing, but like any high-tech equipment, it requires regular maintenance to keep it running smoothly. This guide will walk you through key maintenance tips and considerations for getting the most out of your DTF printer.

Key Considerations Before Purchasing a DTF Printer

-

Daily Use is Crucial

- DTF printers require frequent use to keep the printheads and ink systems functioning properly. If you’re not planning to print every day or frequently, DTF may not be the best fit for you.

- Tip: If you don’t print daily, it might be more practical to outsource your DTF printing to a professional service instead. This can save you from having to invest in regular maintenance and risk damage due to extended idle times.

-

Space & Setup

- Ensure that you have a dedicated space for your DTF printer with a stable, clean environment. Humidity and temperature fluctuations can affect print quality and machine performance.

Daily Maintenance (Before and After Each Print Job)

-

Clean Printheads

- Clean the printheads at the start and end of each printing session to prevent clogging. Use a soft lint-free cloth and isopropyl alcohol to gently wipe the heads.

- Tip: Run a cleaning cycle through your printer if you notice a drop in print quality (banding, missing colors, etc.).

-

Check Ink Levels

- Always monitor ink levels. Low ink can cause poor print quality and damage the printhead. Make sure to have backup ink on hand.

- Tip: Use high-quality inks that are compatible with your printer to avoid clogging and ensure vibrant prints.

-

Monitor the Printer Bed

- Ensure the printer bed is clean and free of any debris or excess ink that could interfere with the print process. Use a lint roller or soft brush to gently clean the surface.

-

Adjust the Print Settings

- Verify the print settings (speed, temperature, and pressure) before starting each job to ensure optimal results.

- Tip: Run a test print regularly to check for any discrepancies in colors or resolution.

Weekly Maintenance

-

Deep Clean the Printhead

- Perform a deep clean once a week to maintain the best quality and prevent any ink build-up that could lead to printhead damage. Use a cleaning solution specifically designed for DTF printers.

-

Check Ink Flow & Hose Connections

- Inspect all ink hoses and connections for any signs of wear or leaks. Ensure there are no blockages or air pockets in the system.

-

Update Software & Firmware

- Make sure your printer’s software and firmware are up to date. This can help with efficiency, new features, and resolving any bugs or issues.

-

Check for Calibration Issues

- Check the printer for calibration issues and realign the printhead if necessary. This ensures accurate color printing and prevents misalignment.

Monthly Maintenance

-

Perform a Full Printer Cleaning

- At least once a month, perform a comprehensive cleaning of the printer, including the printhead, rollers, and internal components.

- Tip: Follow the manufacturer’s recommended procedure to prevent voiding the warranty or causing any unnecessary damage.

-

Replace Consumables

- Check the condition of consumables like transfer film, ink cartridges, and printhead caps. Replace them as needed to ensure optimal performance.

-

Inspect the Printer’s Electrical Components

- Inspect the power cables, connectors, and other electrical components to ensure everything is in working order.

Troubleshooting Common Issues

-

Clogged Printheads

- Symptoms: Lines or missing colors in prints.

- Solution: Perform a cleaning cycle or manually clean the printhead with alcohol and a lint-free cloth. If the issue persists, contact technical support.

-

Ink Smudging or Transfer Issues

- Symptoms: Ink smudging during transfer or poor adhesion to the fabric.

- Solution: Check the curing temperature and time. Make sure your transfer films are compatible and in good condition. You may need to adjust the heat press settings.

-

Poor Print Quality

- Symptoms: Faded or inconsistent prints.

- Solution: Check ink levels, clean the printhead, and ensure proper calibration. Run test prints regularly to check for consistency.

While DTF printing offers amazing results, it requires regular maintenance and daily use to keep it in good working condition. If you don’t plan to print daily or lack the resources for consistent upkeep, it may be better for you to outsource your DTF printing. This can help avoid potential problems with your machine and ensure that your prints remain high quality without the added effort of maintenance.

Conclusion

Maintaining your DTF printer is essential to achieving high-quality prints and prolonging the lifespan of the equipment. If you’re committed to regular use and upkeep, a DTF printer is an excellent investment. However, if you’re not planning to print every day, consider outsourcing your DTF printing to professionals for a hassle-free experience.

Ready to Purchase a DTF Printer or Need Help?

Reach out to us for expert advice, support, and a wide range of top-quality DTF printers that suit your business needs!