Description

Bundle Includes

- PRESTIGE A4 DTF Roll Printer

- DTF Premium Powder 1kg

- Cadlink DTF RIP – Digital Factory DTF Edition Rip for desktop DTF printers (A3 & A4) – For Windows ONLY

- 1 bottle each CMYK + 2 Bottles White Premium DTF Ink 240ml starter pack

- DTF Ink Set CMYKWW –

- DTF Film DS Roll 20 Instant 25– Prestige Premium DTF Film -20cm*25M/roll- Both sides printable – Instant peel.

- DTF Cleaning Fluid 100ml – Cleaning fluid for DTF printer – 100ml

- DTF Maintenance Fluid – DTF Maintenance fluid. Put on a waste ink pad when not using the printer to keep heads

wet and reduce blockages.100ml bottle

- Trim Tool – For cutting the print

- DTF Curing Oven 50 x 40cm

Prestige A4 DTF Printer

Software- Compatible with Windows PC only (no tablets, Surface, etc.)

Presenting the Prestige A4 DTF Printer, DTF Station’s smallest DTF printer ever! Perfect for garment printing enthusiasts starting out with direct to film printing, this desktop printer is available in three color options – classic (black and grey), pink, and mint. It ensures high-quality and reliable results at 9 square feet per hour, and its compact design means you can place this printer just about anywhere.

Features:

- Speed: 9 sq. feet per hour! Fast speed at a comparably low price

- Quality: Epson L805 Print Head

- 3 Color Options: Classic (Black & Grey)

Benefits:

- Size: Compact yet powerful

- Perfect for entry level DTF printing

- Intuitive, elegant design for easy setup and use

What’s Included:

- DigiRIP RIP Software – including fully functional

- 30x Microfiber cloth

- 1x Ink tube (1 meter)

- 5x Ink damper

- 3x 20ml Syringes

- 1x Splash tray

- 10x Cotton Swabs

- 1x Screwdriver

- 10x Disposable plastic gloves

- 1x USB cable

- 1x power cord

- 1x lithium grease

- 1x U-disc

Specifications:

- Printer head: Epson L805

- Mainboard: Epson Original (Converted)

- Interface: USB

- Software: DigiRIP RIP Software

- Printing Width: 7.87″

- Printing Speed: 9 sq ft / hour (1440×720 DPI)

- Machine Weight: 22.71 lbs

- Packaging Weight: 34.17 lbs

- Dimensions:

- Printer (WxLxH): 23″ x 10″ x 8.3″

- Packaging (WxLxH): 32.3″ x 14.25″ x 12.2″

- Daily Output (Based on design size as 7.87″ x 11.81″, 8 hrs per day): 70 pcs

- Suitable Users: Beginners

Applicable Industries:

- Tote Bags

- T-shirts

- Caps

- Garments

- And more!

Fabrics:

- Cotton

- Polyester

- PU

- And more!

Compatible With:

- DigiRIP RIP Software

- DTF Station Seismo S20 Powder Station

- DTF Station Phoenix Air 16×20 Curing Oven

—————————————-

50 x 40cm Curing Oven

Note: It is recommended to turn on the air purifier ONLY while the oven timer is running. Leaving the air purifier on for prolonged periods of time may increase the overall temperature of the oven beyond recommended curing temperature.

The 50 x 40cm Curing Oven is perfect for curing large film sizes, such as 13″ x 19″, 14″ x 16″, 16″ x 20″, and more! This oven comes with a purifier unit built-in to ensure the safety of your production space. It has a digital control unit that is easy to set and allows precise settings of temperature and time for consistent results. A fusing process is started at the touch of a button. After the set time has elapsed, an acoustic signal sounds alerting you to remove the transfer film.

Features:

- Cure Transfers within a minute at 230~248°F

- Bottom Heating Element Rather than Top

- Self Contained Purification system

- Replace Filter 1~3 months depending on usage

Benefits:

- Easy to use

- Built-in purifier – save space & money

What’s Included:

- Handles come unassembled

- Power cord

- Training Video

- Lifetime Tech Support*

- *Only for active customers who have purchased DTF inks or supplies within the last 2 months

Specifications:

- Voltage: 110V

- Power: 0.88KW

- Temperature Range: 0-150°C / 300°F

- Machine Size: 29″W x 21″D x 7.75″H

- Packaging Size: 31″W x 25″D x 10.75″H

- Product Weight: 30 lbs

- Packaging Weight: 35 lbs

The A4 Roll-Fed DTF System offers an excellent starting point for those wanting to explore Direct-to-Film (DTF) printing on a budget. This versatile printer allows transfers onto almost any absorbent material, with users reporting success even on unusual surfaces like diaries. DTF printing shines when working with cotton and other light or dark fabrics, producing bright colors, sharp details, and remarkable wash durability—even after 50 washes, prints retain their vibrant quality.

With DTF’s ability to eliminate cutting, weeding, and image tracing, this technology is fast becoming a go-to for businesses looking for a more cost-effective alternative to heat transfer vinyl.

However, this printer is best suited for those with regular printing needs and a willingness to perform daily maintenance. It’s not recommended for users who only print occasionally or operate in high-temperature environments without air conditioning. For lower volumes, it may be more practical to have your DTF prints handled by a third party.

Quick and Efficient Printing Process

The PRESTIGE A4 completes a full-color A4 print in about 5 minutes, with powder application, curing, and transferring adding an additional 2 minutes. Each system includes top-quality inks, premium DTF film, and high-definition powder with ultra-fine particles (under 80 microns), ensuring crisp and detailed prints. The package also features Fiery Cadlink DTF RIP software for advanced image processing.

Low-Cost Printing

- Film cost (20 x 30cm): R 2.65

- Ink cost: R 3.65

- Powder cost: R 2.75

- Total (with 65% coverage): R 12.05

- Total (with 100% coverage): R 14.60

To account for maintenance expenses, such as future print head replacements, we recommend adding around R 2.00 per print. Even with these costs, DTF remains one of the most affordable transfer methods, especially given its ability to print white ink.

Maintenance is Key

DTF printing does require a bit of hands-on care, including cleaning print heads, managing ink levels, and replacing ink pipes as needed. Regular usage helps prevent clogs, but users can also perform preventive measures to maintain the printer when it’s not in frequent use.

Optional Upgrades for Enhanced Workflow

For those handling larger print volumes, an automatic shaker and curing unit is highly recommended. This setup allows the printer to operate while you manage other tasks, preparing prints for transfer without constant supervision. For smaller operations, powder application can be done manually, and curing can be handled with the optional infrared curing oven. While some may use heat presses or ovens for curing, this can result in uneven results and rejected items.

Key Differences Between DTF and UV-DTF

Please note that this system is distinct from UV-DTF, which is designed for printing stickers on hard surfaces. Some sellers mistakenly advertise UV-DTF systems for fabric printing, but that’s not their intended use.

SourcePrinting Quality Warranty

At SourcePrinting, we provide a limited product warranty on machine parts for the specified periods, including relevant subsystems. This warranty covers defects due to faulty materials or poor craftsmanship during manufacturing. However, it does not cover normal wear and tear or misuse of the machine or its parts.

Printhead – No Warranty

The printhead is a consumable with a limited lifespan and is highly sensitive to voltage fluctuations. Even with an automatic cleaning system, clogging can occur over time, requiring proper maintenance. Partial clogging is expected during usage, even with regular manual cleaning.

✅ For printers purchased from SourcePrinting: We provide training on printhead care during installation.

❌ For third-party machines: We do not offer installation services for separately purchased printheads.

DTF Printer Maintenance Guide for Buyers

Maximize Your DTF Printer’s Lifespan & Performance

Direct-to-Film (DTF) printing is an excellent solution for custom garment and merchandise printing, but like any high-tech equipment, it requires regular maintenance to keep it running smoothly. This guide will walk you through key maintenance tips and considerations for getting the most out of your DTF printer.

Key Considerations Before Purchasing a DTF Printer

-

Daily Use is Crucial

- DTF printers require frequent use to keep the printheads and ink systems functioning properly. If you’re not planning to print every day or frequently, DTF may not be the best fit for you.

- Tip: If you don’t print daily, it might be more practical to outsource your DTF printing to a professional service instead. This can save you from having to invest in regular maintenance and risk damage due to extended idle times.

-

Space & Setup

- Ensure that you have a dedicated space for your DTF printer with a stable, clean environment. Humidity and temperature fluctuations can affect print quality and machine performance.

Daily Maintenance (Before and After Each Print Job)

-

Clean Printheads

- Clean the printheads at the start and end of each printing session to prevent clogging. Use a soft lint-free cloth and isopropyl alcohol to gently wipe the heads.

- Tip: Run a cleaning cycle through your printer if you notice a drop in print quality (banding, missing colors, etc.).

-

Check Ink Levels

- Always monitor ink levels. Low ink can cause poor print quality and damage the printhead. Make sure to have backup ink on hand.

- Tip: Use high-quality inks that are compatible with your printer to avoid clogging and ensure vibrant prints.

-

Monitor the Printer Bed

- Ensure the printer bed is clean and free of any debris or excess ink that could interfere with the print process. Use a lint roller or soft brush to gently clean the surface.

-

Adjust the Print Settings

- Verify the print settings (speed, temperature, and pressure) before starting each job to ensure optimal results.

- Tip: Run a test print regularly to check for any discrepancies in colors or resolution.

Weekly Maintenance

-

Deep Clean the Printhead

- Perform a deep clean once a week to maintain the best quality and prevent any ink build-up that could lead to printhead damage. Use a cleaning solution specifically designed for DTF printers.

-

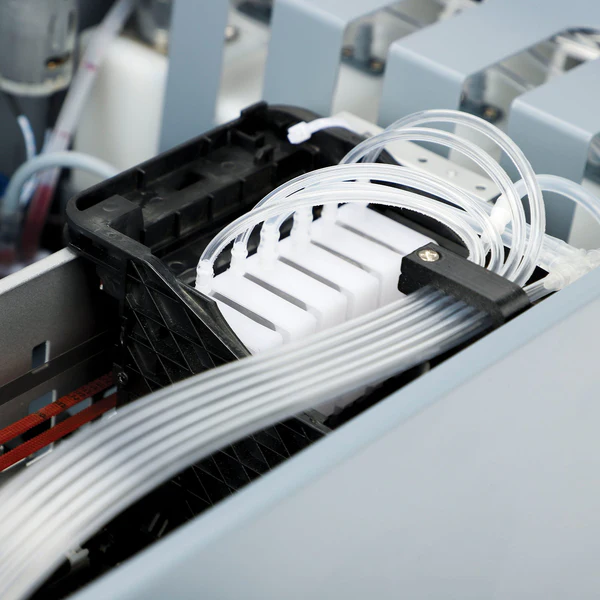

Check Ink Flow & Hose Connections

- Inspect all ink hoses and connections for any signs of wear or leaks. Ensure there are no blockages or air pockets in the system.

-

Update Software & Firmware

- Make sure your printer’s software and firmware are up to date. This can help with efficiency, new features, and resolving any bugs or issues.

-

Check for Calibration Issues

- Check the printer for calibration issues and realign the printhead if necessary. This ensures accurate color printing and prevents misalignment.

Monthly Maintenance

-

Perform a Full Printer Cleaning

- At least once a month, perform a comprehensive cleaning of the printer, including the printhead, rollers, and internal components.

- Tip: Follow the manufacturer’s recommended procedure to prevent voiding the warranty or causing any unnecessary damage.

-

Replace Consumables

- Check the condition of consumables like transfer film, ink cartridges, and printhead caps. Replace them as needed to ensure optimal performance.

-

Inspect the Printer’s Electrical Components

- Inspect the power cables, connectors, and other electrical components to ensure everything is in working order.

Troubleshooting Common Issues

-

Clogged Printheads

- Symptoms: Lines or missing colors in prints.

- Solution: Perform a cleaning cycle or manually clean the printhead with alcohol and a lint-free cloth. If the issue persists, contact technical support.

-

Ink Smudging or Transfer Issues

- Symptoms: Ink smudging during transfer or poor adhesion to the fabric.

- Solution: Check the curing temperature and time. Make sure your transfer films are compatible and in good condition. You may need to adjust the heat press settings.

-

Poor Print Quality

- Symptoms: Faded or inconsistent prints.

- Solution: Check ink levels, clean the printhead, and ensure proper calibration. Run test prints regularly to check for consistency.

While DTF printing offers amazing results, it requires regular maintenance and daily use to keep it in good working condition. If you don’t plan to print daily or lack the resources for consistent upkeep, it may be better for you to outsource your DTF printing. This can help avoid potential problems with your machine and ensure that your prints remain high quality without the added effort of maintenance.

Conclusion

Maintaining your DTF printer is essential to achieving high-quality prints and prolonging the lifespan of the equipment. If you’re committed to regular use and upkeep, a DTF printer is an excellent investment. However, if you’re not planning to print every day, consider outsourcing your DTF printing to professionals for a hassle-free experience.

Ready to Purchase a DTF Printer or Need Help?

Reach out to us for expert advice, support, and a wide range of top-quality DTF printers that suit your business needs!