2130 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining

R 637,500.00

- USD: 40,027.88$

The 2130 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining. From prototyping to full-scale manufacturing, the 2130 ATC can cut and engrave most materials quickly and accurately with its 8-tool magazine. Perfect for large-scale production and just-in-time manufacturing.

- Uses Industry-Standard Software: Ensures compatibility with popular CAM applications.

- Programmable Motorised Z-Axis: Enables precise height adjustments for intricate tasks.

- Pre-Loaded Linear Bearings: Provides smooth and accurate motion for optimal performance.

- Low Maintenance and High Reliability: Engineered for durability and ease of use.

- Solid Cast Steel Frame: Ensures stability and durability, mounted on heavy-duty lockable wheels.

- Durable Vacuum Table: Includes adjustable zones for secure material hold-down.

- Pre-Assembled and Factory-Tested: Shipped as a fully assembled and tested system for immediate use.

- Plug-and-Play Operation: No PC required. Plug in a USB stick and copy your G-code into the controller.

- Versatile Material Compatibility: Cuts and engraves a wide range of materials, including wood, plastics, composites, and non-ferrous metals. Ideal for engraving hard materials like stone and granite.

- Environmentally Friendly System: Quiet and clean operation with low electrical consumption. No harmful gases, liquids, or oils are used or emitted.

- Spare Parts Availability: We supply spares to ensure minimal downtime for your business.

CNC Routers

CNC routers are essential tools for wood cutting, engraving, and 2D relief milling. These versatile machines are perfect for both professional and hobbyist applications, offering precise results for woodworking and milling projects.

Why Choose Our CNC Routers?

- Ideal for cutting and engraving wood materials.

- Capable of 2D relief milling for detailed designs.

- Customizable and reliable solutions for diverse applications.

Contact us today for more information on how our CNC routers can meet your production needs.

Important Information

- Terms & Conditions Apply.

- Prices on our website include VAT.

- Costs for installation, delivery, and training are extra.

- Prices are subject to stock availability.

- Prices and specifications are subject to change without prior notice.

- Training can be arranged on weekends by appointment for our clients.

Available on backorder

Description

The 2130 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining. From prototyping to full-scale manufacturing, the 2130 ATC can cut and engrave most materials quickly and accurately with its 8-tool magazine. Perfect for large-scale production and just-in-time manufacturing.

Key Features

- Uses Industry-Standard Software: Ensures compatibility with popular CAM applications.

- Programmable Motorised Z-Axis: Enables precise height adjustments for intricate tasks.

- Pre-Loaded Linear Bearings: Provides smooth and accurate motion for optimal performance.

- Low Maintenance and High Reliability: Engineered for durability and ease of use.

- Solid Cast Steel Frame: Ensures stability and durability, mounted on heavy-duty lockable wheels.

- Durable Vacuum Table: Includes adjustable zones for secure material hold-down.

- Pre-Assembled and Factory-Tested: Shipped as a fully assembled and tested system for immediate use.

- Plug-and-Play Operation: No PC required. Plug in a USB stick and copy your G-code into the controller.

- Versatile Material Compatibility: Cuts and engraves a wide range of materials, including wood, plastics, composites, and non-ferrous metals. Ideal for engraving hard materials like stone and granite.

- Environmentally Friendly System: Quiet and clean operation with low electrical consumption. No harmful gases, liquids, or oils are used or emitted.

- Spare Parts Availability: We supply spares to ensure minimal downtime for your business.

Technical Specifications

- Spindle Power: 9kW Air-cooled

- Maximum Spindle Speed: 24,000 RPM

- Standard Collet: ISO30

- Control System: NcStudio (Weihong) NK280B controller

- 4th Axis Compatibility: Not standard; inquire for 4th axis/rotary options.

- Axis Drive (X, Y & Z): 1000W Servo Motors

- Working Area (X & Y): 2100 x 3000mm

- Z-Travel: 280mm

- Maximum Working Speed: 25m/min

- Maximum Travel Speed: 40m/min

- Command Code: G-code

- Power Source: 380V

- Repositioning Accuracy: 0.025mm

- Frame: Solid cast steel frame on heavy-duty lockable wheels

- Net Weight: 2000kg (dependent on table selection)

- Warranty: 12 months on the machine; 6 months on the spindle

Related products

-

Laser Cutter & Engraver 300 x 400mm with 40W laser power

R 60,244.00Add to cart- USD: 3,782.65$

-

1325 CNC Router Starter (Vacuum bed)

R 238,250.00Add to cart- USD: 14,959.44$

-

Dental Jewellery Welder Laser Machine

R 317,000.00Add to cart- USD: 19,904.06$

-

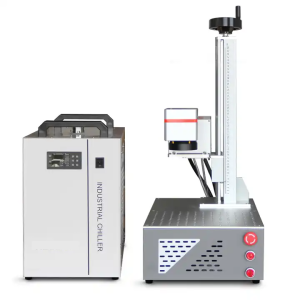

5W UV Laser Marking Machine with Rotary & Chiller Set (220V, 355nm)

R 177,000.00Add to cart- USD: 11,113.62$

-

1300x900mm Cabinet Laser Cutting & Engraving Machine 100W CO2 Laser

R 123,000.00Add to cart- USD: 7,723.03$

-

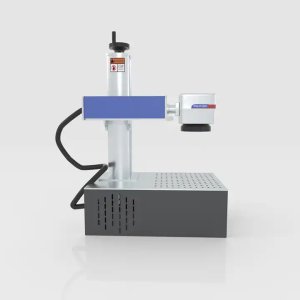

30W Optical-Fiber Laser Marking Machine (220×220mm Lens)

R 72,580.00Add to cart- USD: 4,557.21$

-

1325 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining

R 564,250.00Add to cart- USD: 35,428.60$

-

10W UV Laser Marking Machine with Rotary & Chiller Set – 220V, 355nm

R 279,280.00Add to cart- USD: 17,535.66$

-

Air Assist App Control Offline Engraving Laser Cutting Machine

R 58,000.00Add to cart- USD: 3,641.75$

-

2130 CNC Router (Vacuum Bed) cut and engrave most materials quickly and accurately

R 272,750.00Add to cart- USD: 17,125.65$