VMC1580 Vertical Machining Center CNC Machine

R 2,924,246.00

- USD: 178,667.19$

The VMC1580 is a high-precision Vertical Machining Center designed to meet the demands of medium and high-volume machining in industries such as automotive, aerospace, and precision engineering. With a robust construction, advanced CNC control, and fast response system, this machine delivers exceptional performance for milling, drilling, and tapping tasks.

Available on backorder

Category: Laser And CNC Machine

Tags: 24 Tool CNC Machine, 4th Axis CNC, 5th Axis CNC, Arm Type Tool Magazine, CNC Machine for Complex Machining, CNC Machine with Automatic Tool Change, CNC Machine with Fanuc Control, CNC Machine with High-Precision Control, CNC Machining Center, CNC Machining for Aerospace Components, CNC Machining for Automotive Parts, CNC Milling, CNC Milling for Aerospace, CNC Milling for Automotive Parts, CNC Milling for Medical Parts, CNC Milling for Precision Parts, CNC Milling for Steel, CNC Vertical Milling for Small Batch Production, Fanuc CNC Controller, Heavy Duty CNC Milling, high-precision CNC machine, High-Speed CNC Machining, Industrial CNC Milling Machine, Precision CNC Machine., Siemens 828D CNC Control, Vertical CNC Machine for High-Speed Cutting, Vertical CNC Milling Machine, Vertical Machining Center for Manufacturing, Vertical Machining Center for Metal, Vertical Milling Center, VMC Milling Machine, VMC1580 Vertical Machining Center

Description

What You Can Do with the VMC1580 Vertical Machining Center CNC Machine

The VMC1580 is an advanced Vertical Machining Center that allows you to perform a wide range of precise machining operations. Here’s what you can do with this machine:

Key Operations:

-

Milling

-

Face Milling: Smooth surface finish and high precision.

-

Slot Milling: Create slots of various sizes and shapes in the workpiece.

-

End Milling: Ideal for cutting flat surfaces, grooves, or contours.

-

Keyway Milling: Used for making keyways in shafts or pulleys.

-

-

Drilling

-

Precision Drilling: Drill holes with high accuracy in metal, plastic, and other materials.

-

Counterboring & Countersinking: Achieve a smooth and precise finish for bolts and other fasteners.

-

-

Tapping

-

Thread Tapping: Cut internal threads in drilled holes for bolts, screws, and other fasteners.

-

-

Surface Finishing

-

Use the machine to achieve smooth surface finishes on parts requiring high-quality finishes.

-

-

Complex Machining

-

Multi-Axis Machining (with optional 4th/5th axis support): Perform complex cuts and shapes that require rotating the workpiece to different angles.

-

-

Precision Manufacturing

-

Ideal for making high-precision parts for automotive, aerospace, and industrial applications that require tight tolerances.

-

VMC1580 Vertical Machining Center CNC Machine

Overview

The VMC1580 is a high-precision Vertical Machining Center designed to meet the demands of medium and high-volume machining in industries such as automotive, aerospace, and precision engineering. With a robust construction, advanced CNC control, and fast response system, this machine delivers exceptional performance for milling, drilling, and tapping tasks.

Key Features

1. Precision & Accuracy

- Processing Precision: 0.01 ~ 0.02 mm

- Ensures high-precision machining of complex parts with tight tolerances.

2. Advanced CNC Control

- Standard Control: Fanuc Oi-MF CNC controller

- Optional Control: Siemens 828D, KND-2000M CNC control system

- Provides intuitive programming, reliability, and seamless operation for both CNC and MNC processing.

3. Fast Tool Changes & Flexible Tooling

-

Arm-Type Tool Magazine: 24-tool capacity with manipulator tool change

➡ Reduces downtime and increases productivity with rapid tool changes.

Optional Features:

- Coolant through spindle system: For efficient cooling during high-speed cutting operations.

- Automatic chip conveyor system: Keeps work area clean, improving machine uptime.

4. Sturdy & Reliable Design

- Two Linear Guideways + One Box Way: Offers superior stability and ensures fast response and high-accuracy machining.

- Four Linear Guides for Y-Axis: Provides excellent stability and precision in the Y-axis movement.

5. Efficient Cooling System

-

High-Lift Water Pump: Large flow cooling system to ensure sufficient cooling even under high-speed cutting conditions. Helps improve tool life and part finish quality.

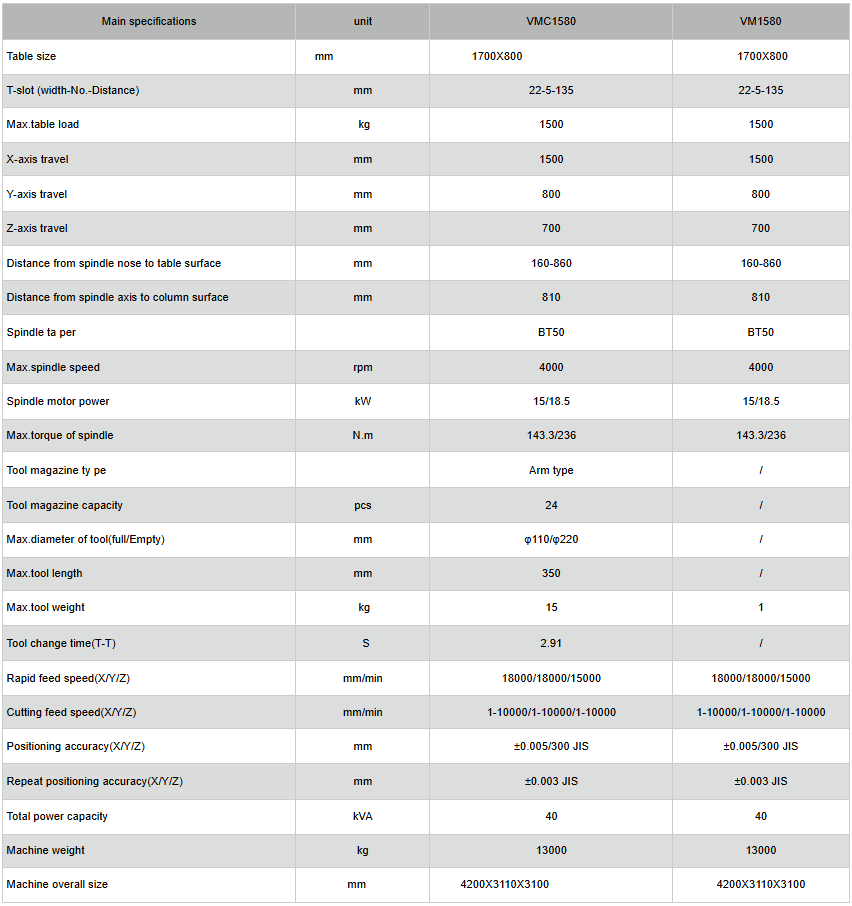

Technical Specifications

| Feature | Details |

|---|---|

| Model Number | VMC1580 |

| Control System | Fanuc Oi-MF (Standard) / Siemens 828D, KND-2000M (Optional) |

| Processing Precision | 0.01 ~ 0.02 mm |

| Tool Magazine Capacity | 24 Tools (Arm Type) |

| Cooling System | Large Flow, High-Lift Water Pump |

| Guideways | Two Linear Guideways + One Box Way |

| Y-Axis Guides | Four Linear Guides |

| Spindle Motor Power | 7.5 kW (Typical) |

| Maximum Speed | 8000 RPM |

| Travel (X/Y/Z) | 1500mm / 800mm / 600mm |

| Machine Dimensions | 2000mm x 2400mm x 2500mm |

| Weight | 5000 kg |

| Certifications | GS, CE |

| Condition | New |

Optional Features

- CNC 4th and 5th Axis Support: Ideal for parts that require multi-axis machining.

- Weida Self-Made Gearbox: A heavy-duty option for high torque applications.

- Coolant Through Spindle: Maximizes cooling efficiency during high-speed cutting, improving tool life and machining results.

Applications

The VMC1580 Vertical Machining Center is suitable for a wide variety of applications, including:

- Automotive Industry: Machining engine components, transmission parts, and chassis components.

- Aerospace: Precision parts for aircraft engines, landing gears, and structural components.

- Metalworking & Manufacturing: Suitable for general milling, drilling, and tapping tasks for a range of metals like steel, aluminum, and alloys.

Why Choose VMC1580 Vertical Machining Center?

- Precision & Reliability: Achieve consistent and accurate results with a high-precision control system and sturdy construction.

- Advanced CNC Control: Equipped with Fanuc Oi-MF (or Siemens/KND) for ease of use and precise command over the machining process.

- High Efficiency: Features like the 24-tool magazine, high-lift water pump, and chip conveyor system ensure continuous operation with minimal downtime.

- Flexible Options: Tailor your machine with advanced control systems, coolant through spindle, and automatic tool changers to fit your unique production needs.

- Suitable for a Range of Industries: Ideal for automotive, aerospace, and precision machining industries looking for versatility and precision.

Related products

-

Pro 50w Mini CNC Cutter Router Printer Aluminium Laser Cutting Engraver Machine

R 35,000.00Add to cart- USD: 2,138.45$

-

Ceramic Colour Fiber Laser Marking Paper, 24×36cm – 20 Sheets Per Bag

R 1,800.00Add to cart- USD: 109.98$

-

Portable handheld laser engraving and cutting machine

R 89,000.00Add to cart- USD: 5,437.77$

-

2130 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining

R 637,500.00Add to cart- USD: 38,950.33$

-

1325 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining

R 564,250.00Add to cart- USD: 34,474.86$

-

Laser Engraver Machine with 40W and laser power of 5.5W

R 7,998.00Add to cart- USD: 488.67$

-

Engraving Ring Machine is designed to provide precise engraving on rings up to 30mm in diameter

R 11,119.00Add to cart- USD: 679.35$

-

CNC Router – High-Speed Precision Machining for Prototyping and Manufacturing

R 122,225.00Add to cart- USD: 7,467.77$

-

5W UV Laser Marking Machine with Rotary & Chiller Set (220V, 355nm)

R 177,000.00Add to cart- USD: 10,814.44$

-

Laser Cutter & Engraver 300 x 400mm with 40W laser power

R 60,244.00Add to cart- USD: 3,680.82$