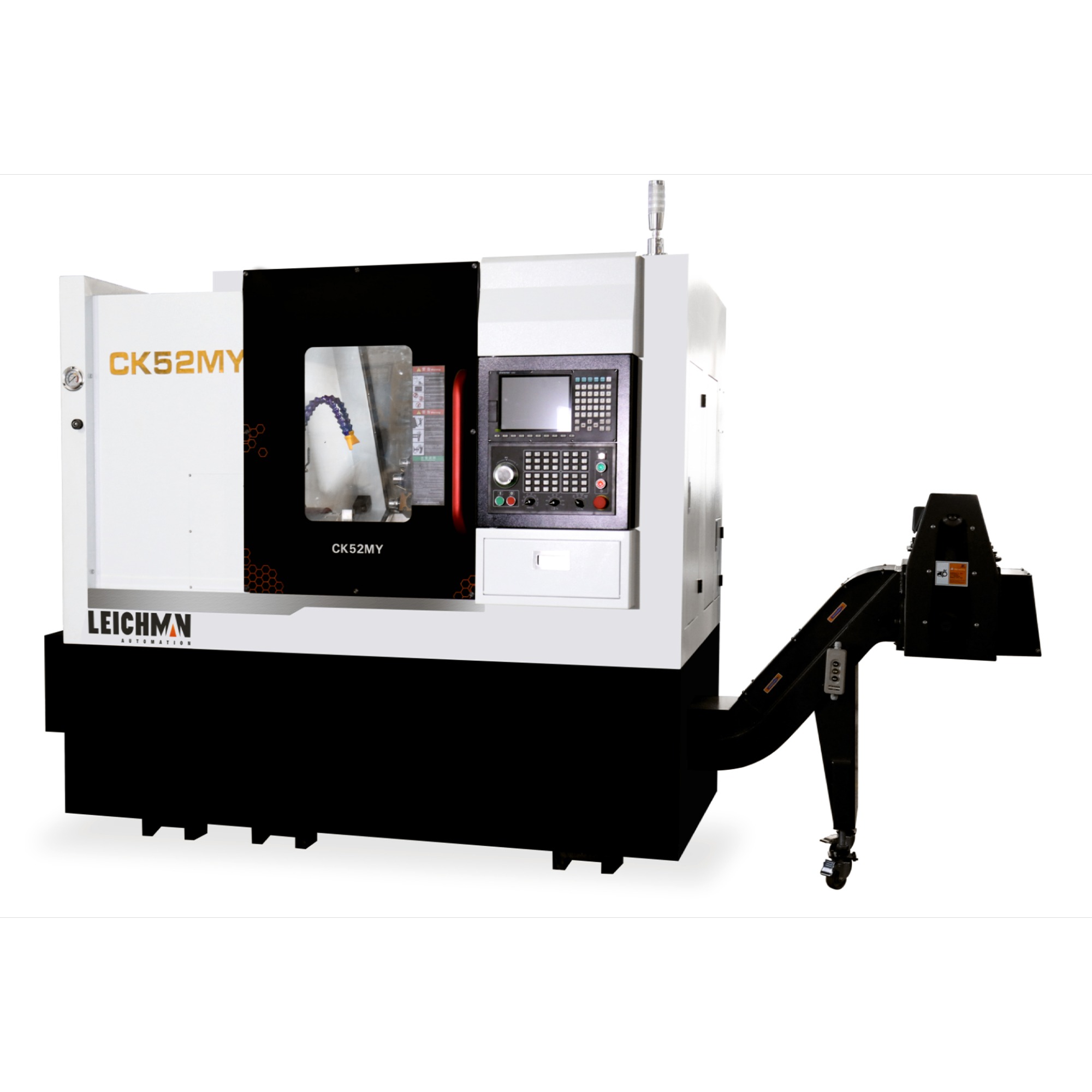

Automatic CNC Lathe Machine Multi-purpose Slant Bed Turning and Milling Center

R 1,020,000.00

- USD: 62,221.68$

The Leichman CK52MY is a high-performance, multi-purpose slant bed turning and milling center designed for precision machining of aluminum, copper, steel, and other materials. With Siemens CNC control options and a robust, well-engineered structure, this lathe is perfect for medium-duty machining, offering excellent accuracy and repeatability across a wide range of industrial applications.

Available on backorder

Category: Laser And CNC Machine

Tags: 12 Station Turret CNC Lathe, 3 Axis CNC Lathe Machine, A2-6 Spindle CNC Lathe, Automatic CNC Lathe Machine, CK52MY CNC Lathe, CNC Lathe FANUC Control, CNC Lathe for Aluminum Steel Copper, CNC Lathe Machine Manufacturer, CNC Lathe Machine Supplier, CNC Lathe Siemens Control, CNC Lathe SYNTEC System, CNC Lathe with Milling, CNC Lathe with Servo Turret, CNC Machine for Metal Parts, CNC Slant Bed Lathe for Sale, CNC Turning and Milling Center, CNC Turning Drilling Threading Machine, CNC Turning Milling Machine, Industrial CNC Turning Machine, Leichman CNC Lathe, Medium Duty CNC Lathe, Metal Cutting CNC Lathe, Multi-purpose CNC Lathe Machine, Precision CNC Lathe Machine, Slant Bed CNC Lathe

Description

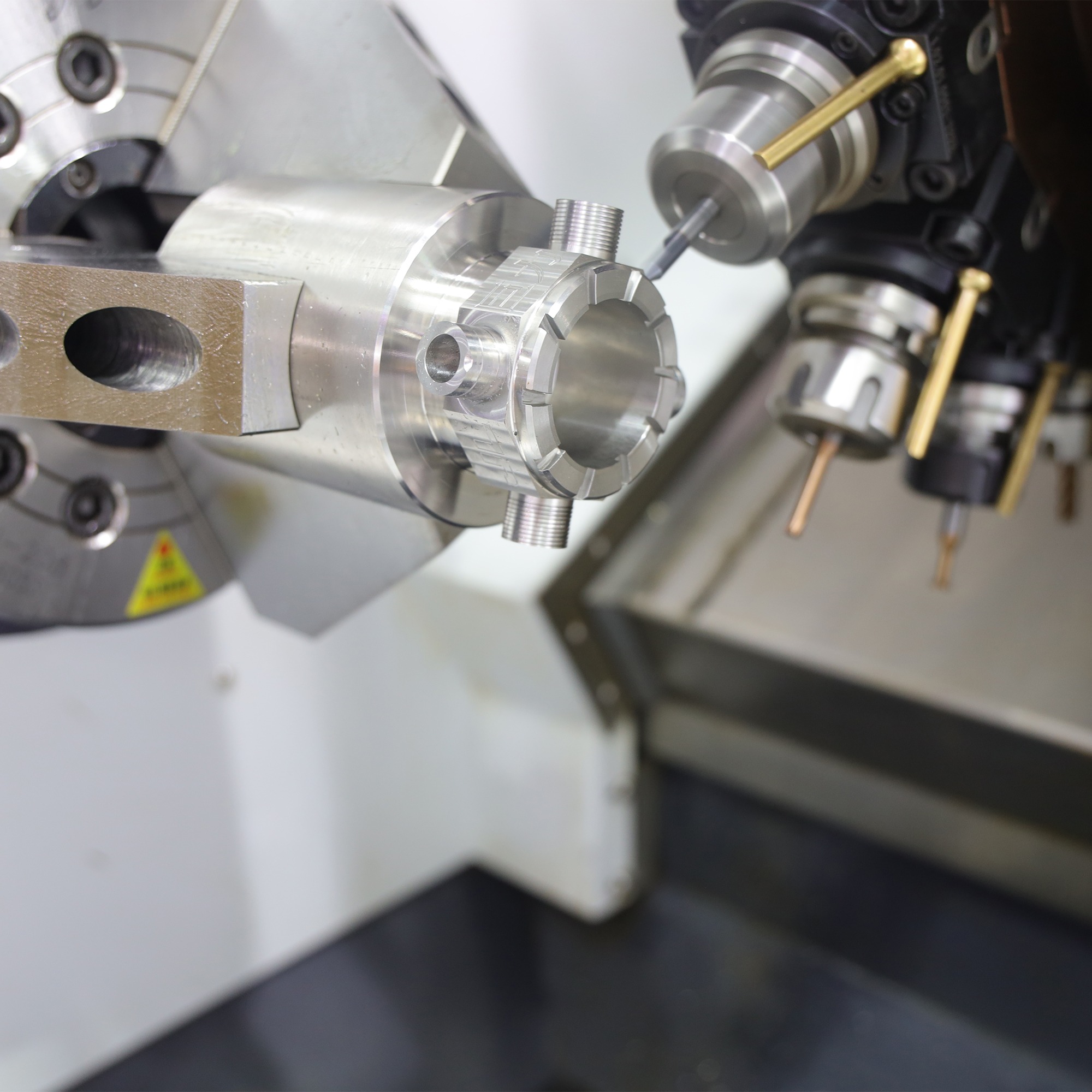

The Automatic CNC Slant Bed Turning & Milling Center (CK52MY) is a multi-purpose CNC machine designed to perform many machining operations in one setup. Here’s a clear breakdown of what this machine can do:

🔧 Machining Operations It Can Perform

1. Turning

- External and internal turning

- Face turning

- Taper turning

- Step turning

➡ Ideal for making round and cylindrical parts such as shafts, bushings, and sleeves.

2. Boring

- Precision internal hole enlargement

- Accurate concentricity for tight tolerances

➡ Used for engine parts, hydraulic components, and bearing housings.

3. Drilling

- Center drilling

- Axial drilling

- Cross drilling (with milling capability)

➡ Eliminates the need for a separate drilling machine.

4. Threading

- External threads

- Internal threads

- Metric and imperial threads

➡ Perfect for screws, fasteners, pipe fittings, and connectors.

5. Milling (Light to Medium Duty)

- Slot milling

- Keyway cutting

- Flat surface milling

- Side milling

➡ Allows complex features on turned parts without removing the workpiece.

🧠 Advanced CNC Capabilities

- 3-Axis CNC control (X / Y / Z) for complex machining

- 12-station servo turret for automatic tool changes

- High repeatability (±0.002 mm) for mass production

- Positioning accuracy ±0.004 mm

🧱 Materials It Can Machine

- Aluminum

- Copper

- Steel

- Alloy metals

- Other machinable metals

🏭 Industries & Applications

- Automotive parts (shafts, hubs, connectors)

- Aerospace components

- Electrical and electronic parts

- Hydraulic and pneumatic components

- General precision manufacturing

- Job shops and mass production lines

⚙️ What Makes It Special

✔ Combines turning + milling + drilling + threading in one machine

✔ Reduces setup time and human error

✔ Slant bed design improves chip removal and accuracy

✔ Heavy cast-iron body minimizes vibration

✔ Ideal for medium-duty, high-precision production

✅ In Simple Words:

This machine can take a raw metal bar and finish it into a fully machined, high-precision part—without moving it to another machine.

Automatic CNC Lathe Machine Multi-purpose Slant Bed Turning and Milling Center

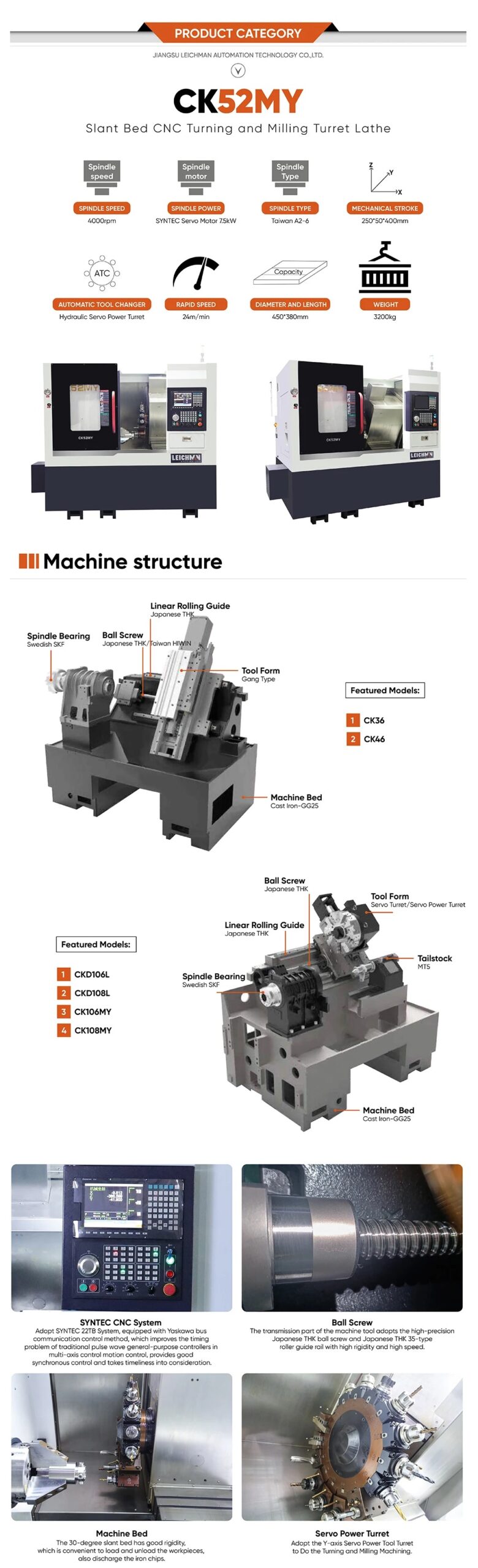

Overview

The Leichman CK52MY is a high-performance, multi-purpose slant bed turning and milling center designed for precision machining of aluminum, copper, steel, and other materials. With Siemens CNC control options and a robust, well-engineered structure, this lathe is perfect for medium-duty machining, offering excellent accuracy and repeatability across a wide range of industrial applications.

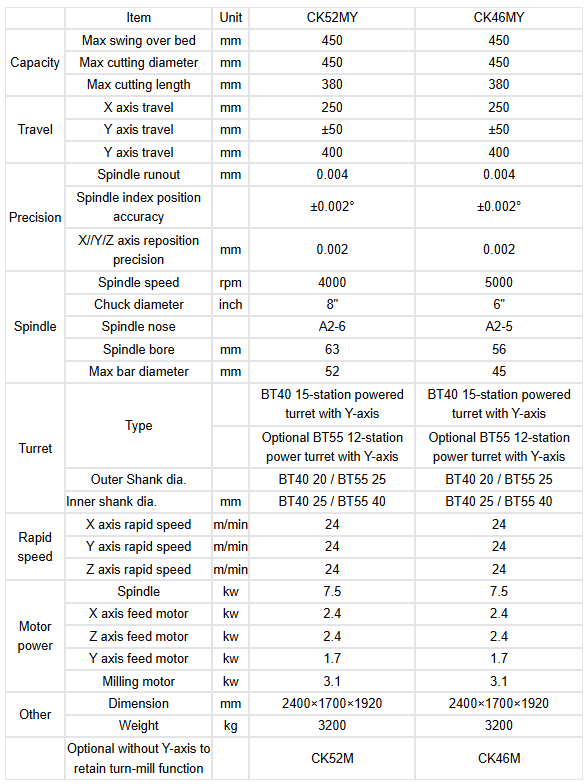

Key Features & Specifications

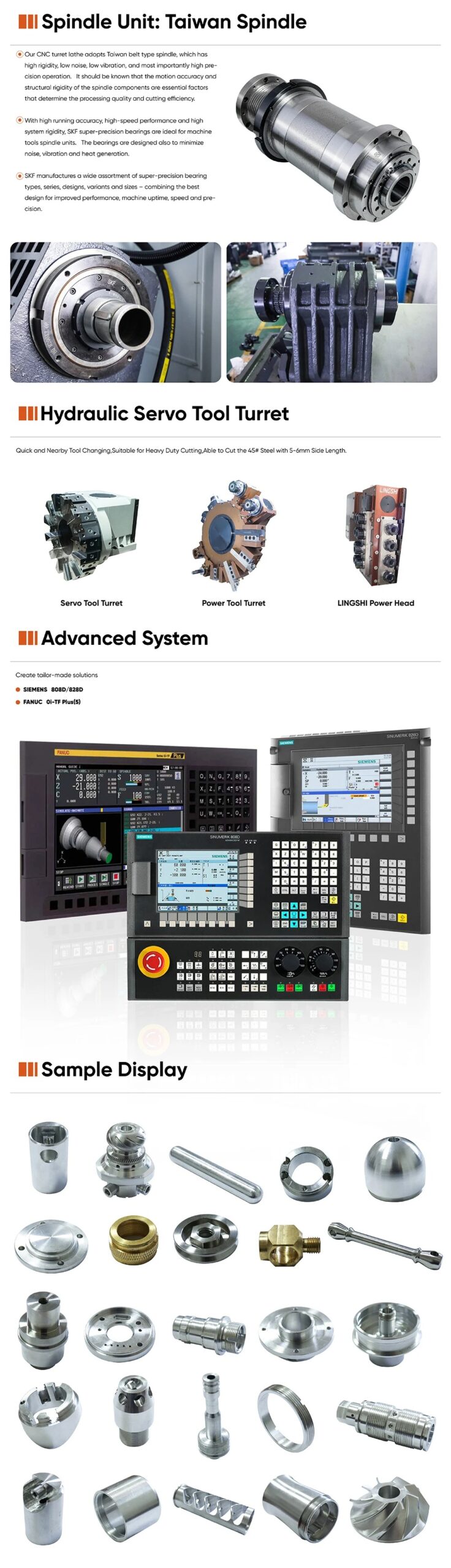

- Control System: Taiwan SYNTEC (Siemens, GSK, FANUC, and KND available as options)

- Spindle Motor Power: 7.5 kW

- CNC Type: CNC Lathe with Turning, Boring, Drilling, and Threading capabilities

- Axes: 3 Axes (X, Y, Z)

- Number of Spindles: Single

- Tool Post Stations: 12 Station Servo Turret (A2-6 spindle nose)

- Travel (X-Axis): 250 mm

- Travel (Z-Axis): 400 mm

- Max Swing Diameter: 450 mm

- Max Workpiece Length: 380 mm

- Chuck Size: 6” / 8”

- Bed Width: 250 mm

- Weight: 3200 kg

- Dimensions (LWH): 2400 x 1700 x 1920 mm

- Warranty: 1 Year

- Material: Aluminum, Copper, Steel, and other metals

Machining Capacity

This multi-purpose CNC lathe machine offers reliable turning, boring, drilling, and threading capabilities with a variety of material types. Its medium-duty design makes it ideal for both small and larger batch productions with high machining precision.

Precision & Repeatability

-

Automatic Repeatability (X/Y/Z): ±0.002 mm

-

Positioning Accuracy: ±0.004 mm

The machine ensures superior precision in every operation, delivering consistent results with minimal deviation, which is ideal for industries that demand tight tolerances.

Design & Construction

-

Slant Bed Design: The bed of the machine is inclined at a 30° angle to provide easy chip removal and facilitate smooth operation. The integrally cast iron base ensures superior shock resistance, reducing vibrations and offering greater stability during operation.

-

Tool Post and Carriage: The large carriage and tool post are inclined, improving both accessibility and operational ease. The 12-station servo turret further adds flexibility and enhances productivity by allowing faster tool changes.

Ease of Operation

Equipped with an intuitive CNC control system, the Leichman CK52MY is suitable for operators at all levels. The system allows for efficient programming and quick setup times, boosting production efficiency.

Machine Applications

- Aerospace Component Machining

- Automotive Parts Manufacturing

- Precision Manufacturing for Various Industries

- Prototyping and Small Batch Production

Product Material

- Aluminum

- Copper

- Steel

- Other Metals (customizable per material requirements)

Customer Support

- Video Outgoing Inspection: To ensure your machine is up to standard before shipment.

- After-Sales Service: Full customer support with training and troubleshooting assistance.

- Warranty: 1-year manufacturer warranty for parts and labor.

Packing and Shipping

- Packing Size: 2400 mm x 1700 mm x 1920 mm

- Gross Weight: 3200 kg

- Selling Units: Single item

Custom Options

-

Control Systems: Choose from Siemens, GSK, FANUC, or KND to suit your production environment.

-

Color: Optional colors based on customer preferences.

Why Choose the Leichman CK52MY CNC Lathe?

-

Unmatched Precision: With repeatability up to ±0.002 mm and accuracy up to ±0.004 mm, you can count on consistently high-quality parts.

-

Heavy-Duty Construction: The machine’s cast iron base and slant bed design ensure durability and minimize deformation during operation.

-

Enhanced Productivity: The 12-station servo turret and Siemens/GSK/FANUC control systems ensure fast tool changes and efficient workflow.

-

Versatile Applications: Whether it’s aluminum, steel, or copper, this lathe handles a variety of materials with ease.

-

Global Support: With video inspections, warranty coverage, and a reliable customer service team, you’re supported throughout your machine’s lifecycle.

If you’re looking for a high-precision CNC lathe that can handle both turning and milling tasks, the Leichman CK52MY is your perfect choice.

Related products

-

2130 ATC-8T is the best value industrial proposition workhorse for large jobs, offering high-speed precision machining

R 637,500.00Add to cart- USD: 38,888.55$

-

Desktop 600×400mm CO₂ Laser Engraving and Cutting Machine 80W

R 65,820.00Add to cart- USD: 4,015.13$

-

2130 CNC Router (Vacuum Bed) cut and engrave most materials quickly and accurately

R 272,750.00Add to cart- USD: 16,638.20$

-

Dental Jewellery Welder Laser Machine

R 317,000.00Add to cart- USD: 19,337.52$

-

Portable handheld laser engraving and cutting machine

R 89,000.00Add to cart- USD: 5,429.15$

-

Laser Engraver Machine with 40W and laser power of 5.5W

R 7,998.00Add to cart- USD: 487.89$

-

Milling Machine VMC1160 CNC Vertical Machining delivers stable cutting for heavy-duty production.

R 1,300,000.00Add to cart- USD: 79,302.14$

-

Ortur Laser Master 3 Lite 10W Laser Engraving Engraver Machine

R 19,250.00Add to cart- USD: 1,174.28$

-

Laser Cutter & Engraver 300 x 400mm with 40W laser power

R 60,244.00Add to cart- USD: 3,674.98$

-

Air Assist App Control Offline Engraving Laser Cutting Machine

R 58,000.00Add to cart- USD: 3,538.10$