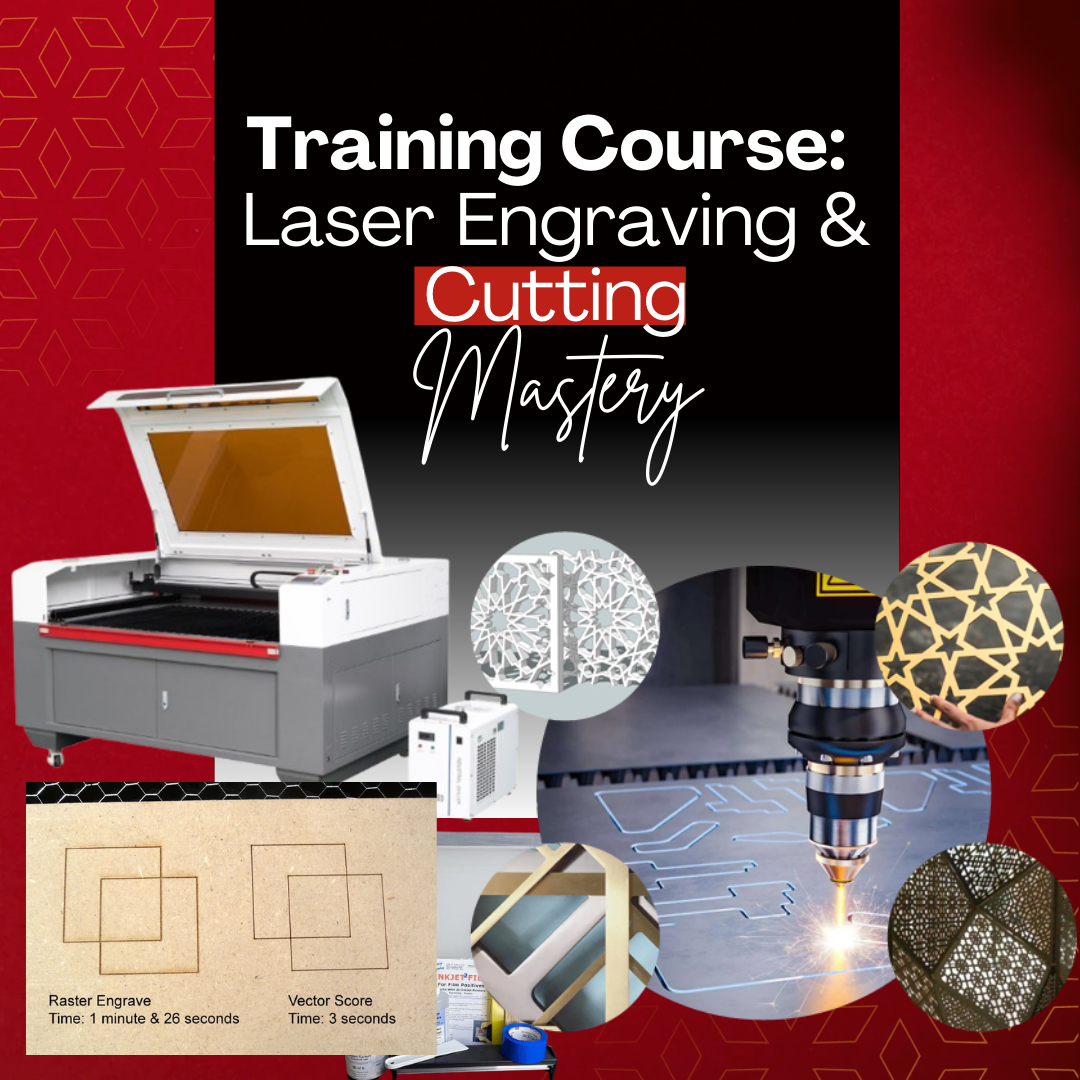

Training Course: Laser Engraving & Cutting Mastery

R 14,999.00

- USD: 935.63$

In person Training is done in Pretoria Gauteng. The cost is per person. Our training runs weekly. Should you need our team to travel out to you let us know. We train nationwide or cross border, please contact us for a formal quote at [email protected]

Training Location:

📍Office Park, 48 Calliandra St, Montana

📍381b Veldkornet Roos St Wolmer, Pretoria North

Training Course: Laser Engraving & Cutting Mastery

Duration: 2-3 Days

Format: In-person or online (live or pre-recorded)

Extras:

- Live Q&A & Support Group Access

- Step-by-Step PDF Guide & Maintenance Checklist

- Certificate of Completion

Category: Training

Description

In person Training is done in Pretoria Gauteng. The cost is per person. Our training runs weekly. Should you need our team to travel out to you let us know. We train nationwide or cross boarder, please contact us for a formal quote at [email protected]

Training Location:

📍Office Park, 48 Calliandra St, Montana

📍381b Veldkornet Roos St Wolmer, Pretoria North

Training Course: Laser Engraving & Cutting Mastery

Duration: 2-3 Days

Format: In-person or online (live or pre-recorded)

Day 1: Introduction to Laser Engraving & Cutting

-

Understanding Laser Technology

- How laser engraving and cutting work

- Types of laser machines (CO₂, fiber, diode)

- Common applications (wood, acrylic, metal, leather, glass, etc.)

-

Laser Machine Components & Setup

- Overview of machine parts (laser tube, mirrors, lens, bed, air assist)

- Software setup (LightBurn, RDWorks, EZCAD for fiber lasers)

- Safety precautions (fume extraction, eye protection, ventilation)

-

Design & File Preparation

- Best software for laser engraving (CorelDRAW, Illustrator, AutoCAD)

- Vector vs. raster engraving

- Preparing artwork for cutting and engraving

Day 2: Machine Operation & Hands-On Training

-

Laser Engraving & Cutting Settings

- Understanding power, speed, and frequency settings

- Focus adjustments for engraving depth and precision

- Testing materials for optimal results

-

Practical Session: Engraving & Cutting on Different Materials

- Wood, acrylic, leather, metal, glass, and more

- Creating custom signage, branding, and promotional products

- Troubleshooting common issues (burn marks, misalignment, low power)

-

Rotary Attachment & Specialty Engraving

- Engraving on cylindrical objects (bottles, tumblers, pens)

- Using jigs for mass production

- Combining laser engraving with UV printing and sublimation

Day 3: Maintenance, Troubleshooting & Business Tips

-

Laser Machine Maintenance & Calibration

- Cleaning the lens, mirrors, and laser bed

- Checking and aligning mirrors for optimal performance

- Replacing and maintaining the laser tube

-

Advanced Troubleshooting Techniques

- Fixing engraving depth inconsistencies

- Resolving software and connectivity issues

- Managing overheating and airflow problems

-

Business & Scaling Up

- Pricing strategies for laser-engraved products

- Bulk production tips

- Marketing and branding strategies

Extras:

- Live Q&A & Support Group Access

- Step-by-Step PDF Guide & Maintenance Checklist

- Certificate of Completion

Related products

-

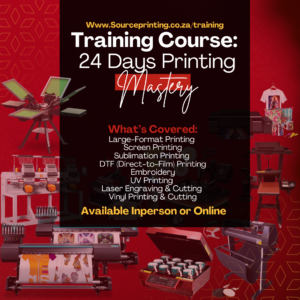

24 Days Printing Mastery

R 68,000.00Add to cart- USD: 4,241.81$

-

Training Course: DTF (Direct-to-Film) Printing Mastery

R 14,999.00Add to cart- USD: 935.63$

-

Training Course: Large-Format Printer Mastery

R 14,999.00Add to cart- USD: 935.63$

-

Training Course: Embroidery Mastery

R 14,999.00Add to cart- USD: 935.63$

-

Training Course: UV Printing Mastery

R 14,999.00Add to cart- USD: 935.63$

-

Training Course: Screen Printing Mastery

R 14,999.00Add to cart- USD: 935.63$

-

Training Course: Vinyl Printing & Cutting Mastery

R 14,999.00Add to cart- USD: 935.63$

-

Training Course: Sublimation Printing Mastery

R 14,999.00Add to cart- USD: 935.63$